Catalog excerpts

Clean, easy to use, reliable casting Newest Technology! Vacuum and Pressure Casting with Muffle Heating A Guktepost for Future Technology

Open the catalog to page 1

Excellent Casting Casting Machine Cast Sam pie-Smooth Surface

Open the catalog to page 2

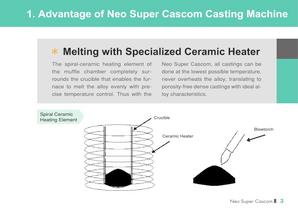

1. Advantage of Neo Super Cascom Casting Machine Melting with Specialized Ceramic Heater The spiral-ceramic heating element of the muffle chamber completely sur- rounds the crucible that enables the fur- nace to melt the alloy evenly with pre- cise temperature control. Thus with the Neo Super Cascom, all castings can be done at the lowest possible temperature, never overheats the alloy, translating to porosity-free dense castings with ideal al- Spiral Ceramic Heating Element Ceramic Heater

Open the catalog to page 3

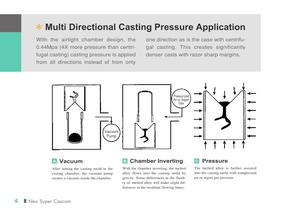

Multi Directional Casting Pressure Application With the airtight chamber design, the 0.44Mpa (4X more pressure than centri- fugal casting) casting pressure is applied from all directions instead of from only one direction as is the case with centrifu- gal casting. This creates significantly denser casts with razor sharp margins. After setting the casting mold in the casting chamber, the vacuum pump creates a vacuum inside the chamber. □ Chamber Inverting □ Pressure With the chamber inverting, the melted alloy flows into the casting mold by gravity. Some differences in the fluidi- ty of...

Open the catalog to page 4

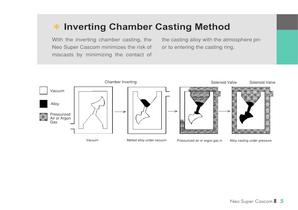

Inverting Chamber Casting Method With the inverting chamber casting, the Neo Super Cascom minimizes the risk of miscasts by minimizing the contact of the casting alloy with the atmosphere pri- or to entering the casting ring. Chamber Inverting Solenoid Valve Solenoid Valve Melted alloy under vacuum Pressurized air or argon gas in Alloy casting under pressure

Open the catalog to page 5

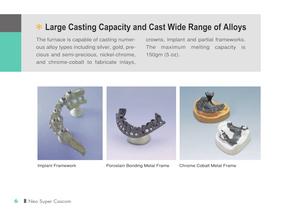

Large Casting Capacity and Cast Wide Range of Alloys The furnace is capable of casting numer- ous alloy types including silver, gold, pre- cious and semi-precious, nickel-chrome, and chrome-cobalt to fabricate inlays, crowns, implant and partial frameworks. The maximum melting capacity is Implant Framework Porcelain Bonding Metal Frame Chrome Cobalt Metal Frame

Open the catalog to page 6

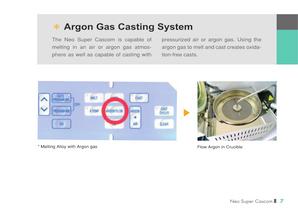

Argon Gas Casting System The Neo Super Cascom is capable of melting in an air or argon gas atmos- phere as well as capable of casting with pressurized air or argon gas. Using the argon gas to melt and cast creates oxida- tion-free casts.

Open the catalog to page 7

* Compact Size and Easy Set up Compact desktop size enables use in addition, the Neo Super Cascom is the smallest space. The Neo Super Cas- cooled by air and thus no expensive Wa- com does not require over 200V electrici- ter line construction is required. ty, just require the regular household. In The unit compact in design allows you to set up easily in the laboratory within a dental clinic office with the power outlet of 120V, 1.5KW, equivalent to that of the general houses. JKNote : The argon gas tank is necessary for the alloys that need argon gas to cast. Contact KDF US Inc. for more...

Open the catalog to page 8

Economical Advantage Since the flame from the blowtorch heats the alloy from one direction, some portion of the alloy will evaporate into melted alloy. Furthermore, in centrifugal casting, about 5% of the melted alloy is lost in splashing. The Neo Super Cas- com prevents any loss of alloy by evapor- ation or being splashed. Easy and Stabilized Castings Computerized system requires no skilled operation and enables you to obtain stabil- ized castings. * Safe and Clean Environment KDF Neo Super Cascom will contribute to offer safe and clean laboratory with work en- vironment free of noise.

Open the catalog to page 9

Turn the switch on the front right side of the unit up- ward to power on. If start temp has been program- med, it will start heating up toward the start temp. □ Easy Set up Casting Program Two methods of programming are provided. One is Auto Program Mode, the other is Manual Program Mode. Once accurate program has been set up, the unit memorizes the program up to 100 programs.

Open the catalog to page 10

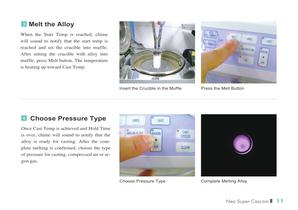

When the Start Temp is reached, chime will sound to notify that the start temp is reached and set the crucible into muffle. After setting the crucible with alloy into muffle, press Melt button. The temperature is heating up toward Cast Temp. Insert the Crucible in the Muffle Press the Melt Button □ Choose Pressure Type Once Cast Temp is achieved and Hold Time is over, chime will sound to notify that the alloy is ready for casting. After the com- plete melting is confirmed, choose the type of pressure for casting, compressed air or ar- Choose Pressure Type Complete Melting Alloy

Open the catalog to page 11

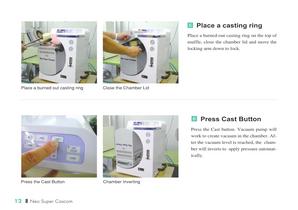

B Place a casting ring Place a burned-out casting ring on the top of muffle, close the chamber lid and move the locking arm down to lock. Place a burned out casting ring Close the Chamber Lid □ Press Cast Button Press the Cast button. Vacuum pump will work to create vacuum in the chamber. Af- ter the vacuum level is reached, the cham- ber will inverts to apply pressure automat- Press the Cast Button Chamber Inverting

Open the catalog to page 12

Cast Finished After cooling time is finished, the cham- ber returns to its original position automati- cally. Open the chamber lid and remove the casting ring and crucible. The Neo Su- per Cascom creates the beautiful castings. Chamber returns I mplant Framewo rk Implant Framework

Open the catalog to page 13

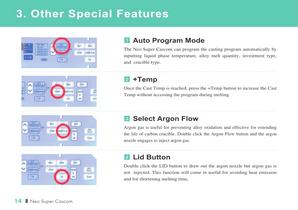

3. Other Special Features □ Auto Program Mode The Neo Super Cascom can program the casting program automatically by inputting liquid phase temperature, alloy melt quantity, investment type, Once the Cast Temp is reached, press the +Temp button to increase the Cast Temp without accessing the program during melting. Select Argon Flow Argon gas is useful for preventing alloy oxidation and effective for extending the life of carbon crucible. Double click the Argon Flow button and the argon nozzle engages to inject argon gas. Double click the LID button to draw out the argon nozzle but argon gas...

Open the catalog to page 14

Ceramic Crucible Counter To prevent damage due to cracked or broken crucibles, the unit has a cruci- ble counter. The counter keeps track of Hi/Lo temperature melting to cal- culate the maximum cast count. Even from a remote location, the pocket buzzer will beep 5 minutes be- fore the end of the melt cycle (at one minute intervals) allowing the techni- cian to concentrate on other work. Press VIBES button to slightly shake the muffle and to facilitate the view- ing of alloy melting situation easily.

Open the catalog to page 15All KDF catalogs and technical brochures

-

Catalog

13 Pages

-

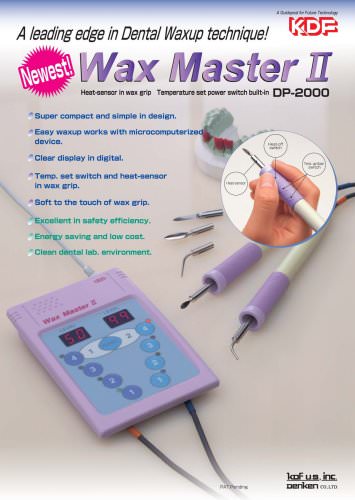

Wax Master II Brochure

2 Pages

-

007EX Burnout Furnace

2 Pages

-

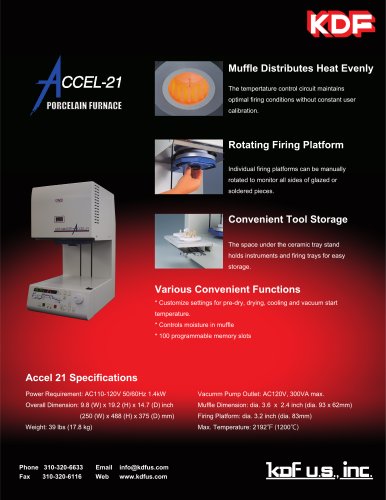

Accel 21

1 Pages

-

MasterS Brochure

2 Pages