Website:

The LEE Company

Website:

The LEE Company

Catalog excerpts

Technical Hydraulic Handbook Eleventh Edition 2009

Open the catalog to page 1

Lee products with complete engineering data. THE LEE COMPANY TECHNICAL CENTER 2 Pettipaug Road, P O. Box 424 Westbrook, Connecticut 0649S-0424 U.S.A. Phone: 860 399-6281 800 533-7584 (LEE PLUG) Fax: 860 399-7058 (order entry)

Open the catalog to page 3

IntroductionU.S. Sales Offices Westbrook, Connecticut Tel: 860 399-6281 ct-sales@theleeco.com Chicago, Illinois Tel: 773 693-0880 il-sales@theleeco.com Tampa, Florida Tel: 813 287-9293 fl-sales@theleeco.com Dallas/Ft. Worth, Texas Tel: 972 791-1010 tx-sales@theleeco.com Detroit, Michigan Tel: 248 827-0981 mi-sales@theleeco.com Huntington Beach, California Tel: 714 899-2177 ca-sales@theleeco.com Distributor for Belgium, Netherlands and Luxemburg Denis de Ploeg BV Tel: + 31 43 820 0250 bs.deploeg@ddp.nl Distributor for Australia and New Zealand Aviaquip Pty. Ltd. Tel: + 61 3 9585 1211...

Open the catalog to page 4

Introduction Distributor for Taiwan Loop Link Enterprise, Inc. Tel: + 886 2 2762 9614 looplink@ms9.hinet.net Agent for South America Trusty Comercio e Representagoes Ltda. Tel: + 55 12 3132-3418 rui@tcr-brazil.com.br Agent for Israel eNl Engineering & Logistics Ltd. Tel: + 972 3 549 3644 Agent for India Hind Industrial & Mercantile Corp. Pvt. Ltd. Tel: + 91 22 2493 3545 info@hindco.net Agent for Singapore, Indonesia, Thailand and Malaysia Winova Tel: +65 6425 2116 THE CONTINUING STORY OF LEE COMPANY INNOVATION For over 60 years, The Lee Company has pioneered the design and...

Open the catalog to page 5

The Lee Company maintains a ratio of one engineer per seven employees. This commitment to technology allows Lee to offer the best products and technical support available. The Lee Company has over 700,000 square feet of modern manufacturing and office space at four sites located in Westbrook and Essex, Connecticut. Almost all of the manufacturing of Lee products including machining, molding, assembling and testing is performed in-house at these two facilities. We are equipped with the latest production equipment as well as a sophisticated computerized production control system. Substantial...

Open the catalog to page 6

QUALITY POLICY The Lee Company’s Quality Policy ensures that we are able to comply with the requirements of AS9100. The commitment ensures continually improving the effectiveness of the Quality Management System, quality objectives, targets, and measurements of objectives. The Mission of The Lee Company is to design and build state-of-the-art products that exceed customers’ expectations for utility, performance, and quality. The Lee Company constantly strives to improve the product designs, the manufacturing process, and the quality system. The ultimate goal is zero defects and a satisfied...

Open the catalog to page 7

The Industrial MicroHydraulics (IMH) group supplies Lee Betaplugs, Hi-Performance Cheks, and other miniature fluid control components to the automotive, commercial and industrial markets. IMH products meet the requirements for quality, economy and ease of automated installation, which are of paramount importance to these industries. The Lee Company is committed to full professional service to our customers through a worldwide sales network of graduate engineers. Lee has sales offices in Huntington Beach, Chicago, Tampa, Dallas, Detroit, and at the Technical Center in Westbrook. Lee also has...

Open the catalog to page 8

Introduction SPECIAL PRODUCTS The Lee Company offers many miniature flow control components other than the standard products described in this handbook. In fact, approximately 50% of all Lee products are special or custom items designed to meet the requirements of a specific application. The majority of these special products are minor variations of standard products and may differ only slightly in: lohm rate, cracking pressure, leakage, flow testing, materials, etc. . . The remainder are uniquely different from the “standards” described in this handbook and include the following: •...

Open the catalog to page 9

VIII Products

Open the catalog to page 10

Special Products

Open the catalog to page 11

Lee Piloting Solenoid Valves Pressure Components

Open the catalog to page 15

□ Proof Pressures up to 32,000 psid □ Sizes from .093" to .656" in Diameter □ Aluminum, Stainless Steel or Monel Models Available □ High Pressure Plugs Available LEE PLUG R.F.O. (RADIAL FORCE ONLY) □ No Downward Pressure During Installation □ No Support Shoulder Required □ Ideal For Thin Wall Applications □ Easily Removable

Open the catalog to page 17

Lee Plug Removable Plug, seals R.F.O. in thin walls without Lee Plug Removable, reusable plug A.F.O. for high pressure, high temperature applications ..51 - 53 Lee High For High Strength, High Strength Hardness materials, and

Open the catalog to page 18

Introduction LeeTHE PRINCIPLE OF LEE PLUG PERFORMANCE The Lee Plug is a cylindrical plug with a tapered hole part way through its center and numerous small grooves on its outside diameter. It is slipped into a reamed counterbore in the product. A tapered pin is then driven into the plug until the ends of the pin and the plug are flush with each other. Controlled expansion causes the lands and grooves of the plug to “bite” into the surrounding material forming independent seals and retaining rings. Result: a positive, reliable, leak and trouble-proof seal for both liquids and gases. This...

Open the catalog to page 19

Lee Plugs are manufactured to exacting tolerances. Every process is precisely controlled. Critical dimensions are 100% checked and others are statistically checked. All plugs and pins are 100% visually inspected. In addition, every lot of Lee Pins and Plugs is production acceptance tested. A representative sample of the mating pin or plug are performance tested to a Lee Company process specification for installation, leakage, pin retention, proof pressure and thermal stability. Two certificates of performance (one for the pin lot and one for the plug lot) accompany every shipment of Lee...

Open the catalog to page 20

and chemical limits per Lee Company specification. We do not approve the use of material meeting only the 416 specification. PLUG PROOF PRESSURE To assist designers in the proper selection of Lee Plugs, a “proof pressure” is given for up to three hole tolerances (Classes I, II, III). The Lee Plug proof pressure is the highest hydrostatic pressure that may be applied in the course of routine Production Acceptance testing. The Lee Plug proof pressure values stated in this Handbook are defined for Lee Plugs when installed into boss materials identical to that of the Plug. When installing Lee...

Open the catalog to page 21All The LEE Company catalogs and technical brochures

-

LPD SERIES

1 Pages

-

LHQ SERIES

1 Pages

-

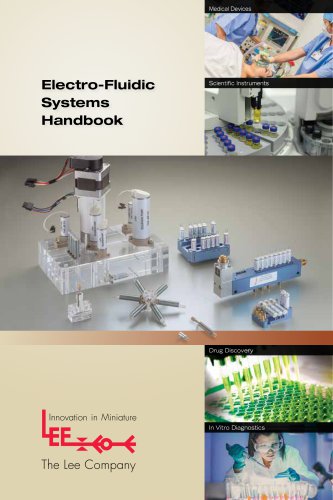

Electro Fluidic Systems

2 Pages

-

Electro-Fluidic Systems

323 Pages

-

LEE LATCHING SOLENOID VALVE

1 Pages