Website:

MCQ Instruments

Website:

MCQ Instruments

Catalog excerpts

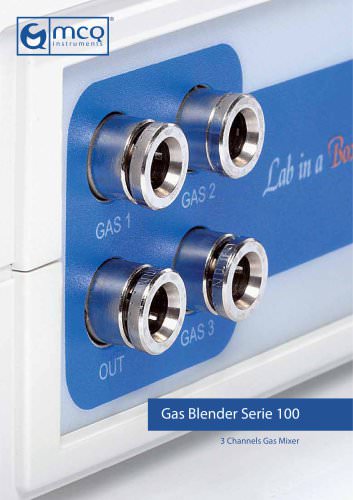

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface Application Note High precision mixtures for carbon nanotubes (CNT) development MCQ Gas Blender 100 Series CVD-related Application Introduction Nanotechnology field research represents today one of the ultimate science frontier, as astonishing promising as incredible hard to achieve. Nano-sized materials application offers new exciting possibilities for revolutionary goal achievements and for further development in almost every scientific branch. What could only be imagined a few years ago may now become real. In this new wave that’s getting the future one step closer to modern science, Carbon NanoTubes (CNTs) and related wide set of possible applications represent one of the more complex, studied and promising system. Applications Carbon nanotubes are allotropes of carbon, organized in a specific form called graphene, arranged in a cylindrical nanostructure. The CNTs structure, related to the peculiar atoms arrangement in space, gives CNTs the physical and chemical unique properties on which the great scientific interest grown around in the last decade. The simplest CNTs space configuration is the single-walled nanotube (SWNT) but structures made of different concentric nanotubes nested within one another, called multi-walled nanotubes (MWNT) can also be synthesized. These MWNT are especially interesting due to their telescoping property (inner nanotubes may slide, almost without friction, within its outer shell) that makes them a perfect example of molecular machine nanotechnology. Their structure makes CNTs the strongest and stiffest material yet discovered in terms of tensile strength and elastic modulus, while, due to their hollow structure and high aspect ratio, they tend to undergo buckling when, for example, placed under bending stress. The CNTs graphene structure also strongly affects its electrical properties, making them moderate semiwww.mcqinst.com conductors. Electrochemical properties for supercapacitor applications are also well known. However, what makes CNTs so extraordinary special its their dependence of nanotubes size and aspect-ratio, changing what it’s possible to manage and consequently tune CNTs features to desired values. CNTs can be done at different lengths, angles and curvatures resulting in an unparalleled tunable and versatile material. Process optimization CTNs are currently synthesized using different deposition techniques, particularly Plasma Enhanced Chemical Vapor Deposition (PECVD) and Hot Filament Chemical Vapor Deposition (HFCVD). Both have strengths and weaknesses and there’s still a debate on which is best for CNTs applications [1,2]. However both techniques follow the same procedure steps for the nanotubes synthesis: Substrate preparation: metal catalyst nanoparticles (usually Ni, Co, Fe) are placed like a thin layer on the substrate in order to act as nuclei for the CNTs grown. High magnification carbon nanotubes micrograph Gas Blender 100 Series Application Note

Open the catalog to page 1

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface Substrate annealing: the substrate is heated to approximately 700°C to activate the grown reaction. Self-assembly CNTs structure grown by CVD Gas Blending: a process gas (ammonia, nitrogen, hydrogen) and a carbon-source gas (acetylene, ethylene, ethanol or methane) are mixed and flown into the reactor chamber. CNT grown: the hydrocarbon gas mixture is thermally activated (fragmented) by the catalyst nanoparticles on which the so formed carbon fragments give rise to the nanotubes. Size, structure and quality of...

Open the catalog to page 2

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface [5] C. Du and N. Pan, CVD growth of carbon nanotubes directly on nickel substrate – Mater Lett 59, 13 (2005) 1678-1682. [6] S. Wei, W.P. Kang, J.L. Davidson and J.H. Huang, Aligned carbon nanotubes fabricated by thermal CVD at atmospheric pressure using Co as catalyst with NH3 as reactive gas – Diamond Relat Mater 15, 11-12 (2006) 1828-1833. [7] Y.M. Wong, S. Wei, W.P. Kang et al., Carbon nanotubes field emission devices grown by thermal CVD with palladium as catalysts – Diamond Relat Mater 13, 11-12 (2004)...

Open the catalog to page 3All MCQ Instruments catalogs and technical brochures

-

GB NANO 3

4 Pages

-

GB 15k

2 Pages

-

GB 2000

4 Pages

-

GB 3000

4 Pages

-

GB 3000

4 Pages

-

GB 4000

4 Pages

-

GB 6000

4 Pages

-

GB 100

4 Pages

-

GB 100 plus

4 Pages

-

SensorModule

7 Pages

-

Sensor Module

7 Pages

-

Gas Blender Advantages

4 Pages

Archived catalogs

-

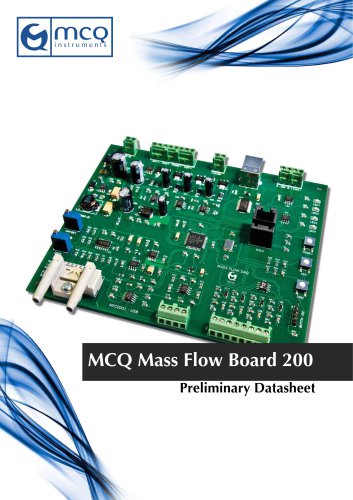

Flow Board

11 Pages

-

Gas Blender 106 Series

4 Pages

-

Data acquisition board

4 Pages