Website:

MCQ Instruments

Website:

MCQ Instruments

Catalog excerpts

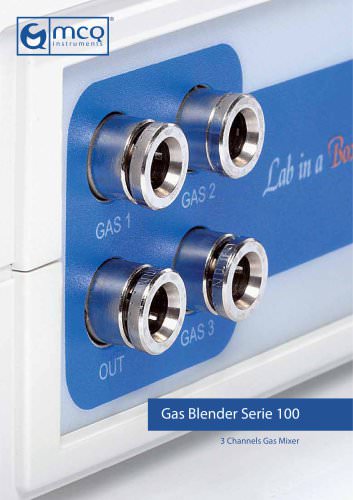

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface Application Note PVD/CVD hard coatings for anti-wear tools and components development MCQ Gas Blender 100 Series CVD-related Application Introduction Tools and machinery components are the key instruments of every industrial production. During their working lifetime, tools and components are subjected to intensive degradation due to the combined erosive and abrasive wear and due to the corrosive attack of agents. This degradation shortens the instruments lifetime with a direct impact on process productivity. For an industrial country the costs related to the maintenance/substitution of tools and components can reach 4% of Gross Internal Product (GIP). For all these reasons it is fundamental to enhance instruments lifetime and consequently the productivity. The commonly used solution to enhance tools and components performances is the application of protective hard coatings. The substrate of hard coated tools and components is protected by a thin film (generally few micrometers thick) of hard materials whose main features are high hardness and chemical inertness. Brittle and expensive, these hard protective coatings are usually inappropriate for bulk tool material but turn to be extremely effective for thin films applications. Hard coatings are applied to substares Titanium Nitride Coating CVD Diamond Coating Appearance of drills with different coatings. through Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). Both these techniques share the need of a highly accurate and controlled gas mixture in order to obtain the desired results. The MCQ solves this need with its Gas Blender 100 Series, a professional instrument for precision gas mixtures preparations and dynamic gas mixtures management. Material choice All the tools and the machinery components are subjected to wear. Hard protective coatings have been specifically implemented to reduce wear and therefore increasing the instruments lifetime. For each process there are different types of wear mechanisms the tools are subjected to (e.g. abrasion, adhesion, corrosion, high temperature, material sticking etc.). Therefore, in order to choose the most suitable coating material, it is very important to know which mechanism has the highest contribution to wear. Currently there are two material families capable of fulfilling the majority of the industrial process needs: the ceramic materials and the CVD synthetic diamond. Ceramic Materials Ceramic materials is a generic term that refers to a large family of compounds, characterized by high hardness and chemical inertness. The main compounds used for hard coatings applications are nitrides and carbides of transition metals, especially titanium (Ti), chromium (Cr) and zirconium (Zr). These types of hard coatings are not only suitable for anti-wear applications. Each compound has peculiar features that contribute to enhance the material The three major sources of renewable enhance utility. Titanium nitride (TiN) coatings greatly energy: the sun, wind and biomass exploitation substrates wear and corrosion resistance but they are also Gas Blender 100 Series Application Note

Open the catalog to page 1

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface The main advantages of hard coating deposition for tools technology application: Solar Panel A thick films and anti-wear components. Hard Coating Improved anti-wear resistance used for medical implants applications (due to their non-toxic nature) and for decorative purposes (due to the TiN gold appearance). Titanium carbide (TiC) and chromium nitride (CrN) are especially suitable for corrosion and oxidation protective coatings while zirconium nitride (ZrN) is ofter used for its refractoriness properties. CVD...

Open the catalog to page 2

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface properties [1-3], while a dynamic management of the gas phase can be used to deposit high-performance multilayered coatings [4]. For CVD diamond applications, managing the gas phase is crucial. The gas phase is commonly composed by a hydrogen/methane mixture, with hydrogen as activation gas and methane as carbon source. Concentration of carbon-containing species has significant influence on growth rate, quality and morphology of deposited diamond [5-7]. Small changes in the gas mixture composition can affect the...

Open the catalog to page 3All MCQ Instruments catalogs and technical brochures

-

GB NANO 3

4 Pages

-

GB 15k

2 Pages

-

GB 2000

4 Pages

-

GB 3000

4 Pages

-

GB 3000

4 Pages

-

GB 4000

4 Pages

-

GB 6000

4 Pages

-

GB 100

4 Pages

-

GB 100 plus

4 Pages

-

SensorModule

7 Pages

-

Sensor Module

7 Pages

-

Gas Blender Advantages

4 Pages

Archived catalogs

-

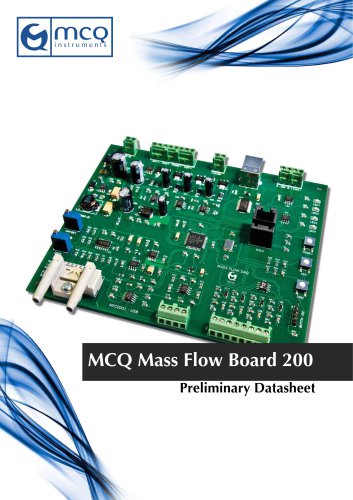

Flow Board

11 Pages

-

Gas Blender 106 Series

4 Pages

-

Data acquisition board

4 Pages