Website:

MCQ Instruments

Website:

MCQ Instruments

Catalog excerpts

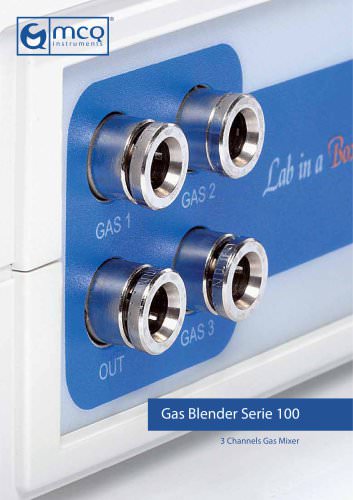

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface Application Note The use of high precision gas mixtures for Modified Atmosphere Packaging (MAP). An MCQ Gas Blender 100 Series Application Introduction What is MAP? The commerce globalization and the constantly increasing demand for food pushed in recent years the goods shelf life improvement to become a central research topic developed world wide. Interaction between oxygen and food usually causes chemical oxidation and aerobic microorganisms growth, the major causes of food spoilage. Chilling the goods can help in slowing the deterioration of stored foods but it’s the oxygen concentration reduction in the atmosphere surrounding the product that considerably increases the shelf-life. The oxygen reduction and others atmosphere modifications are performed by techniques as known as Modified Atmosphere Packaging (MAP). MAP in constant development MAP techniques are now the major packaging method used on a wide range of fresh or chilled foods (more detailed information will be discussed further). Even if the majority of products share the same spoilage causes, each food has its own optimal MAP configuration that maximizes the shelf life enhancement. This is the main reason that leads the scientific community to a constant research for new and more refined solutions. The optimization of MAP processes mostly relies on the atmosphere surrounding the foods, focusing today research on different gas mixtures experimentation. MCQ solution MAP development lab-applications thus require working with high precision gas mixtures and quick and easy mixture management methods. For all these applications, MCQ proposes the use of the Gas Blender 100, an instrument specificcaly designed for in lab experimentation that allow the user to create three component dynamic gas mixtures and that offers an intuitive way to manage them with the MCQ Gas Mixer Manager software. Map Applications Major MAP applications regard the storage and quality preservation of fresh and cured meat [1-3], seafood products [4-6], fruits and vegetables [7-10] and other generic foods [11-16]. The products are usually minimally processed thus the MAP solves the main role in their shelf life extension. The common modified atmospheres are composed by oxygen, nitrogen and carbon dioxide mixed together in different proportions depending on the product and the needs of manufacturer and the consumer. Less common but still used are those applications that involve carbon monoxide [2,17,18], nitric oxide [19] and nitrous oxide [20,21] as modified atmosphere gaseous components. Gas Blender 100 Series Application Note

Open the catalog to page 1

High Performance Gas flowDilutor& Gas flow Mixing System with User Interface Table 1. Atmosphere used in MAP Atmosphere composition used as a filler gas because of its low solubility in water and lipid compared with that of carbon dioxide, thus preventing pack collapse. Fruit/vegetables / /J~~?J~~? Cured meat / // / White Fish / // // / Fatty Fish / // / Pasta (with meat) / // The presence of oxygen (and in small amount, of carbon monoxide) primarily contributes to maintain the fresh meat oxygenated, giving the product the bright red color commonly associated with a good freshness degree....

Open the catalog to page 2

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface more efficiency and an innovative quick and easy way for mixtures management, all in a compact case. The Gas Blender 100 works with 3 components gas mixtures, each gas media connected to a dedicated instrument channel for which MCQ guarantees high accuracy (1.0% of set point), high repeatability (0.16% of reading value) and the fastest response time for set point value change (50ms) now available in the market. The instrument works with dry, non-aggressive gases and the channels are always Hardware configuration...

Open the catalog to page 3

High Performance Gas flow Dilutor & Gas flow Mixing System with User Interface References [1] M. García-Esteban, D. Ansorena and I. Astiasarán, Comparison of modified atmosphere packaging and vacuum packaging for long period storage of dry-cured ham: effects on colour, texture and microbiological quality – Meat Sci 67, 1 (2004) 57-63. [2] L. Martínez, D. Djenane, I. Cilla, J. A. Beltrán and P. Roncalés, Effect of different concentrations of carbon dioxide and low concentration of carbon monoxide on the shelf-life of fresh pork sausages packaged in modified atmosphere – Meat Sci 71, 3 (2005)...

Open the catalog to page 4All MCQ Instruments catalogs and technical brochures

-

GB NANO 3

4 Pages

-

GB 15k

2 Pages

-

GB 2000

4 Pages

-

GB 3000

4 Pages

-

GB 3000

4 Pages

-

GB 4000

4 Pages

-

GB 6000

4 Pages

-

GB 100

4 Pages

-

GB 100 plus

4 Pages

-

SensorModule

7 Pages

-

Sensor Module

7 Pages

-

Gas Blender Advantages

4 Pages

Archived catalogs

-

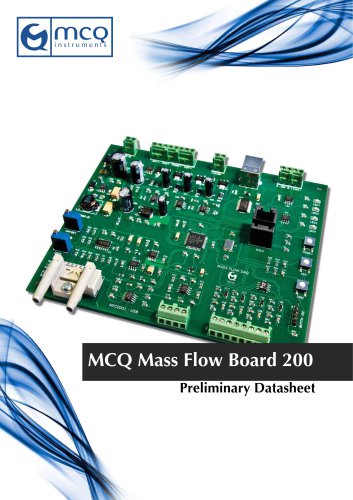

Flow Board

11 Pages

-

Gas Blender 106 Series

4 Pages

-

Data acquisition board

4 Pages