Website:

MDG Engineering S.r.l.

Website:

MDG Engineering S.r.l.

Group: Medical Devices Group S.r.l.

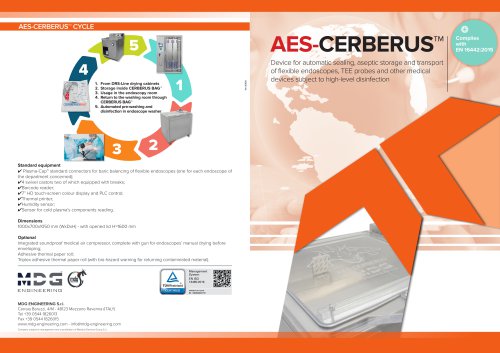

Catalog excerpts

Leak Test automatically performed by the machine during the entire cycle. It guarantees a positive continuous pressure inside the endoscopes avoiding infiltrations. Detergent savings by the automatic adjustable dose. It prevents waste or overdose that could damage scopes. Full Traceability through barcode reader that identifies the operator and the instrument. Consequently, together with the printings of the individual stages of the process, it is possible to track all phases until the final result. Alternatively you can send data to pcs via Bluetooth or Ethernet connection. Time savings allow the operator to perform other tasks inside the cleaning room. In the meantime the device executes the pre-washing of endoscopes automatically. Lowering of biological risks and osteoarticular diseases such as Carpal Tunnel syndrome. UNI EN ISO 15883-5:2006. technical data Main Characteristics ER-214™ helps the operator step by step during all the phases through graphic messages on the display. The device performs these operations automatically: Leak test is performed during all the washing cycle in order to reduce risks of instrument infiltrations. Automatic detergent dosage thanks to the diaphragm pump, it doses the right quantity of detergent reducing risks of waste and overdosage harmful to the instrument. Made of food-grade ABS and stainless Steel 304L. Other components made of materials resistant to aggressive chemical detergents. Outside dimensions (HxDxH) 440x270x220 mm Weight 10 kg Certification Class I, according with Annex VIII of Regulation (EU) 2017/745, EN 61010-1, EN 61010-2-040, EN 60601-1-2, EN 61326-1, EN ISO 14971, UNI EN ISO 15883-5 Annex I and F. Automatic flushing and rinsing of endoscope channels with no reusable product. This avoids the recycling of water used for the cleaning, preventing risks of contamination. Organic residual sample: it is possible to take a sample of water to quickly carry out organic residual tests. Full traceability through paper report or saving data to USB. Data transfer between ER-214™ and pc/server through Bluetooth or Ethernet connection. Practical and fast use through barcode (or manual controls). ER-214™ automatically cleans the instrument in a fast and safe way. The operator only needs to clean scopes outside. MDG ENGINEERING S.r.l. Carraia Baruzzi, 4/M - 48123 Mezzano Ravenna (ITALY) Tel +39 0544 1826013 Fax +39 0544 1826015 www.mdg-engineering.com - info@mdg-engineering.com Company subject to management and coordination of Medical Devices Group S.r.l.. benefits obtained by reprocessing ER-214™ automatic system to support the manual pre-washing steps of flexible endoscopes Compilant with UNI EN ISO 15883-5 ANNEX I and F Compliance according to regulation EU 201

Open the catalog to page 1

SOFT TOUCH RESET-STOP-START BUTTON INTEGRATED PRINTER AND USB PORT DILUTED SOLUTION ASPIRATION Clean-up counter for endoscopy suitable for the automated control with ER-214™ The clean-up counter connected to the ER-214™ automatic system for the reprocessing of the endoscopic channels and the removal of the microbial biofilm, allows the automatic loading / unloading of the water and the dosage of the chemical necessary for the correct cleaning of endoscopes channels. This process allows to avoid recycling of liquids or rather the contamination of all devices. Connection kit for each brand,...

Open the catalog to page 2