Catalog excerpts

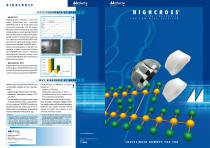

T E S T S P E R F O R M E D B Y M E D A C T A® Regarding wear resistance, it has been widely demonstrated that crosslinked UHMWPE wear is not measurable using normal test parameters. For this reason, Medacta® performed wear tests, simulating critical conditions, matching HIGHCROSS® with CoCrMo heads abraded with hydroxyapatite powder to increase their roughness. The results show that HIGHCROSS® treated liners have significantly greater wear resistance than standard UHMWPE liners. Optical microphotographs of the worn surface after 10 million cycles show that standard UHMWPE liners have no machining marks left (due to the wear process). On the contrary HIGHCROSS® liners still show the lathe machining marks5. } MECHANICAL TEST Regarding the mechanical properties, after artificial aging, HIGHCROSS® better maintains its mechanical properties compared to a 25 kGy gamma ray sterilised UHMWPE. } WEAR TEST cycles (millions) Bottom of the EtO sterilized liner Bottom of the HIGHCROSS® liner W H Y H I G H C R O S S B Y M E D A C T A® Different types of crosslinked UHMWPE are commercially available and are characterised by: }radiation levels between 50 and 100 kGy, }stabilisation temperature between 70°C and 160°C, }final sterilisation with gamma-rays or inert methods (ethylene oxide or gas plasma). Not all crosslinked UHMWPE provides adequate performance, mainly due to low radiation levels, low stabilisation temperatures and final sterilisation with gamma rays. References: 1) Currier, B.H:, Wittman, M.W., “Retrieval Analysis of Crosslinked Acetabular Bearings”, Crosslinked and Thermally treated UHMWPE for Joint Replacements STP1445, ASTM 2004 2) Scott, M., Widding, K., Ries, M., Shanbhag, A., Smith & Nephew, Inc. Memphis. “Wear Particle Analyses of Conventional and Crosslinked Ultra High Molecular Weight Polyethylene Tested in an Anatomic Hip Simulator” 47th Annual Meeting, ORS, Feb. 25-28, 2001, San Francisco, California HIGHCROSS® by Medacta® is characterised by: }radiation at 100 kGy, }stabilisation temperature of 150°C, }controlled cooling rate in order to optimise mechanical properties, }final sterilisation with ethylene oxide. Such innovative production strategies yield a high quality material with enhanced properties. Medacta® has started long term clinical studies to confirm the excellent in vitro and first short-term results. 3) Chiesa, R., Moscatelli, M., Giordano, C., Siccardi, F., Cigada, A., 2004 “Influence of heat treatment on structural, mechanical and wear properties of crosslinked UHMWPE”. Journal of Applied Biomaterials & Biomechanics 2, 20-28. 4) Muratoglu, O.K., Bragdon, C.R., O’Connor, D.O., Delaney, J., Jasty, M., Harris, W.H., 2000. “The comparison of the wear behaviour of four types of crosslinked acetabular components”, 46th Annual Meeting, ORS, March 12-15 2000, Orlando, Florida. 5) Data on files Medacta www.medacta.com Medacta International Strada Regina 6874 Castel San Pietro - Switzerland Phone +41 91 696 60 60 - Fax + 41 91 696 60 66 Info@medacta.ch

Open the catalog to page 1

1}Radiation with gamma or beta rays at dose levels between 50 and 100 kGy, in order to achieve crosslinking. at temperatures between 80°C and 160°C, to eliminate the residual free radicals generated during radiation. 3}Machining of the component, which results in the removal of the superficial oxidised layer. 4}Final sterilisation without radiation to avoid further alteration to the structure. Crosslinking process It has been proven that wear resistance increases proportionally to the radiation level, reaching very low wear values after 100 kGy exposure. 50 kGy radiation eliminates the...

Open the catalog to page 2All Medacta catalogs and technical brochures

-

PowerSuture leaflet

2 Pages

-

PowerKnot leaflet

2 Pages

-

MectaQTH leaflet

2 Pages

-

FairFix leaflet

2 Pages

-

M-ARS ACL leaflet

2 Pages

-

Adult Scoliosis Patient brochure

24 Pages

-

M.U.S.T. SI Patient leaflet

8 Pages

-

MySpine MC Patient brochure

12 Pages

-

Sterile Implants leaflet

10 Pages

-

M.U.S.T. leaflet

2 Pages

-

M.U.S.T. MIS leaflet

2 Pages

-

M.U.S.T. Mini leaflet

2 Pages

-

MectaLIF leaflet

2 Pages

-

MectaLIF Anterior leaflet

2 Pages

-

MectaLIF TIPEEK leaflet

2 Pages

-

Mecta-C leaflet

2 Pages

-

Mecta-C Stand Alone leaflet

4 Pages

-

MySpine S2AI leaflet

4 Pages

-

MySpine MC leaflet

2 Pages

-

MySpine leaflet

2 Pages

-

GASTON leaflet

2 Pages

-

MYHIP leaflet

2 Pages

-

M-VIZION leaflet

5 Pages

-

MPACT System leaflet

2 Pages

-

VERSAFITCUP CC TRIO leaflet

2 Pages

-

MINIMAX leaflet

2 Pages

-

SMS leaflet

3 Pages

-

MASTERLOC leaflet

2 Pages

-

QUADRA System leaflet

2 Pages

-

QUADRA-P System leaflet

4 Pages

-

AMISTEM System leaflet

2 Pages

-

AMISTEM-P leaflet

2 Pages

-

AMIS EXPERIENCE brochure

28 Pages

-

MYSHOULDER patient leaflet

8 Pages

-

MYSHOULDER leaflet

4 Pages

-

MOTO Medial patient leaflet

8 Pages

-

GMK Sphere patient leaflet

8 Pages

-

MyKnee patient leaflet

16 Pages

-

Efficiency KneePack flyer

2 Pages

-

GMK Revision System leaflet

2 Pages

-

MOTO MEDIAL leaflet

4 Pages

-

GMK UNI Anatomic leaflet

2 Pages

-

GMK Efficiency leaflet

2 Pages

-

MyKnee leaflet

4 Pages

-

GMK Primary leaflet

2 Pages

-

GMK Sphere leaflet

3 Pages