Catalog excerpts

INSTALLATION MANUAL ≈QUICK SHIP SURFACE-MOUNTED HEADWALL Model #4540-S

Open the catalog to page 1

Electrical Junction Box, if included, Located Behind Removable Upper Panel Lower Mounting Plate OVERVIEW The Quick Ship Flatwall 4540-S surface-mounted headwall is a UL-listed, configurable medical gas and electric service assembly employing multiple service rows to conveniently locate medical gas, electrical, and communications provisions. The Flatwall comes standard with forward-facing vertical equipment management tracks to mount and organize accessories. The installation of the Flatwall 4540-S surface-mounted headwall is a three-step process: 1. Fasten the Flatwall headwall to the...

Open the catalog to page 2

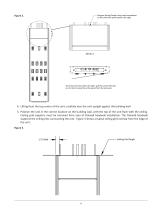

STRUCTURAL BLOCKING: Structural blocking must be provided in areas shown in Figure 1 for proper headwall anchorage. Blocking typically consists of 2”x 6” wood framing members or steel channel, minimum 16 ga. thickness. Blocking must be centered 1.50” down from ceiling line. The width of the blocking must be greater than the width of the headwall to allow for varying site conditions. Figure 1. Structural Blocking IMPORTANT: Wainscoting should not be installed behind the Flatwall unit. Ideally, partial wall coverings should be applied after the unit is installed. If the coverings are to be...

Open the catalog to page 3

Depress Spring Plunger using small screwdriver or #8 screw then push panel to the right Once the panel has slid to the right, pull the panel's left side out to then remove the entire panel from the extrusion. 4. Lifting from the top center of the unit, carefully lean the unit upright against the building wall. 5 . Position the unit in the correct location on the building wall, with the top of the unit flush with the ceiling. Ceiling grid supports must be removed from area of Flatwall headwall installation. The Flatwall headwall supports the ceiling tiles surrounding the unit. Figure 3 shows...

Open the catalog to page 4

6. Ensure the sides of the unit are plumb. 7. Fasten the unit to the structural blocking through the provided upper mounting holes (Figure 4D). Drywall anchors can be installed through lower mounting holes. Figure 4. Upper Mounting Holes C Lower Mounting Holes

Open the catalog to page 5

MEDICAL GAS SERVICE CONNECTIONS Use extreme care in making medical gas service connections. Each single-point service connection has been provided with a color-coded medical gas label. Medical gas systems provided by Modular Services have been cleaned, purged, brazed, blown down, labeled, and tested for cross connections and leaks in accordance with the most recent edition of NFPA 99. They are certified to be compliant to all of these requirements and to be leak free. The medical gas system installer is responsible for connecting this manufactured assembly to the pipeline in compliance with...

Open the catalog to page 6

Vertical Track Adaptors to Forward-Facing Vertical Track 1. Align the Vertical Track Adaptor with the Forward-Facing Vertical Track so that the tee knob is facing towards the center of the unit (Figure 7a). 2. Insert Vertical Track Adaptor into Forward-Facing Vertical Track and slide to desired accessory height (Figure 7b). Figure 7. a.

Open the catalog to page 7

3. Turn tee knob clockwise to secure Vertical Track Adaptor in place (Figure 7c). c. CARE AND MAINTENANCE 1. Clean with mild detergent and warm water. Do not use lubricants or oils on unit. 2. Avoid excessive moisture build-up, as it can damage mechanisms in the unit. 3. Disinfect as required with disinfectant approved by the Environmental Protection Agency. 4. To remove difficult spots or stains, use standard household cleansers and a soft-bristled brush. 5. For parts or repairs, contact your sales representative. INSTALLATION TERMS AND CONDITIONS Each Modular Services unit, or unit...

Open the catalog to page 8

WARRANTY Modular Services Company warrants that all equipment assemblies shall be free from defects in material and workmanship for a period of 12 months from date of the owner’s acceptance to the installing contractor or the date the equipment is put into service, whichever comes first. Warranty excludes electric lamps and/or any material not furnished by Modular Services. Warranty does not cover damage due to improper installation and/or abuse. It is the responsibility of the customer to report any noted product deficiencies to Modular Services immediately upon discovery. It is the...

Open the catalog to page 9All Modular Services Company catalogs and technical brochures

-

Provider Plus® 6540-AC Specs

2 Pages

-

Flatwall 4540-S Specs

3 Pages

-

MOBILE HEADWALL

2 Pages

-

Profile 7200-S Series

2 Pages

-

Method Snapshot

2 Pages

-

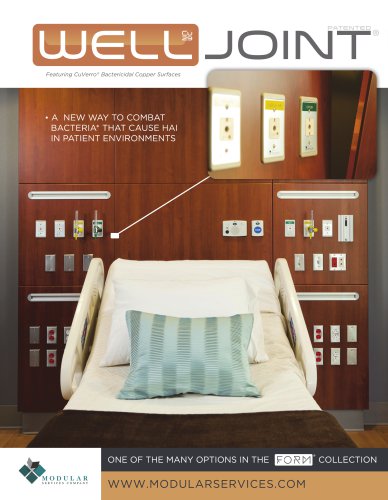

WellJoint®

2 Pages

-

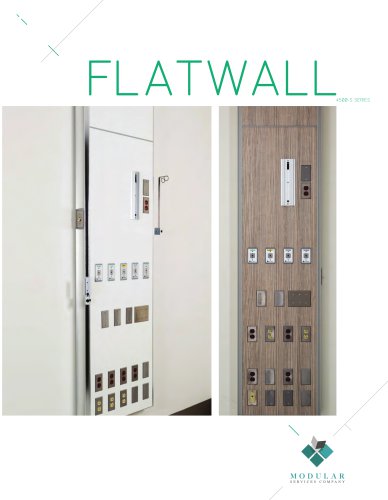

Flatwall 4500-S Series

2 Pages

-

5-Sided Open Access Column

2 Pages

-

Evolution Series

2 Pages

-

Bed Docker Construction

1 Pages

-

ArtWorks-Accessories

4 Pages

-

Long-Term Care

2 Pages

-

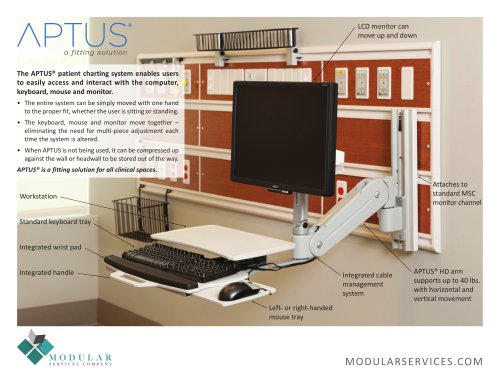

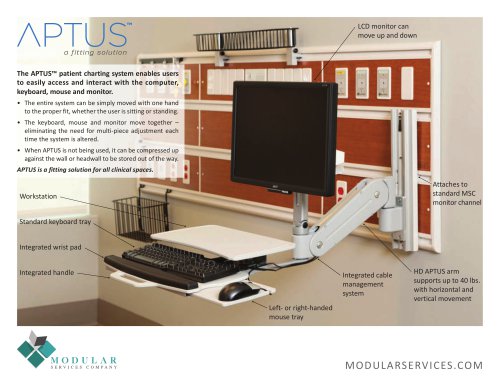

APTUS HD & L

2 Pages

-

APTUS Cart

2 Pages

-

Method

8 Pages

-

NICU

2 Pages

-

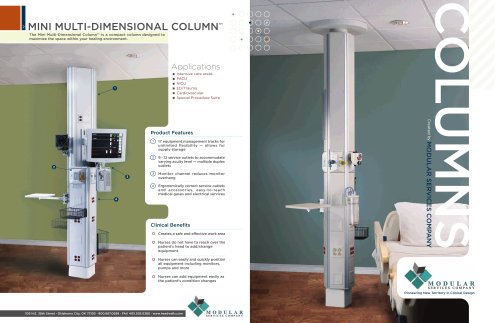

Columns

4 Pages

-

NOVA LED Exam Light

2 Pages

-

SUPER EXAM 50 ®

3 Pages

-

Clarity

2 Pages

-

AMBIANCE ® COLOR CHART

1 Pages

-

Provider Plus

2 Pages

-

2-Gas Profile

2 Pages

-

Profile

8 Pages

-

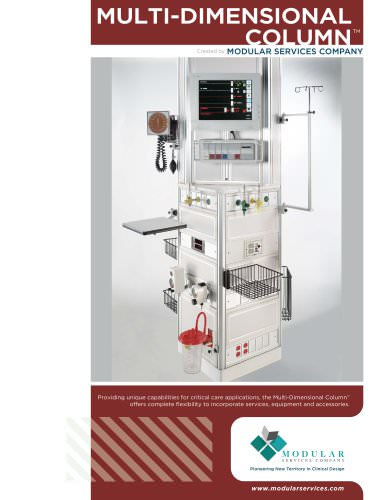

Multi-Dimensional

2 Pages

-

Form

8 Pages

-

Flatwalls

2 Pages

-

Critical Care Cart

2 Pages

-

Console

2 Pages

-

Bed Docker

2 Pages

-

Longterm Care

2 Pages

-

APTUS Laptop Arm

1 Pages

-

AIM LED

4 Pages

-

Ceiling Columns

2 Pages

-

APTUS

2 Pages

-

ArtWorks

4 Pages

-

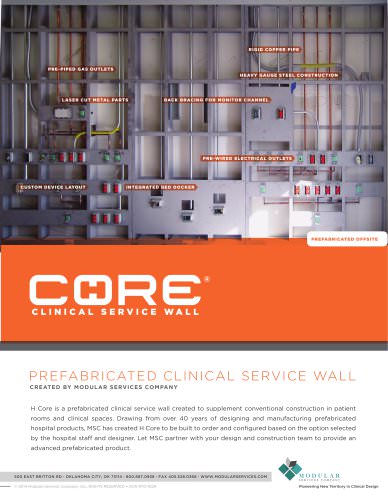

H Core

2 Pages

-

ArtWorks Brochure

2 Pages

-

ambiance_brochure

2 Pages

-

Accessories Brochure

26 Pages

-

5-Sided Column Brochure

2 Pages

-

Columns Brochure

2 Pages