Catalog excerpts

LARGE SIZE ROLLING BEARINGS

Open the catalog to page 1

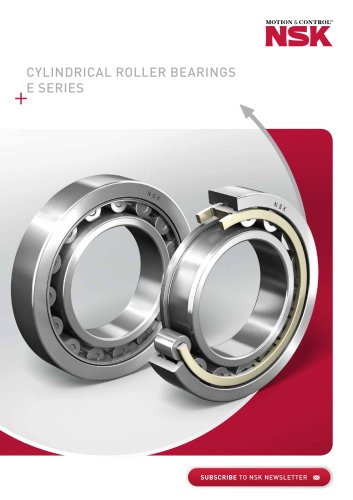

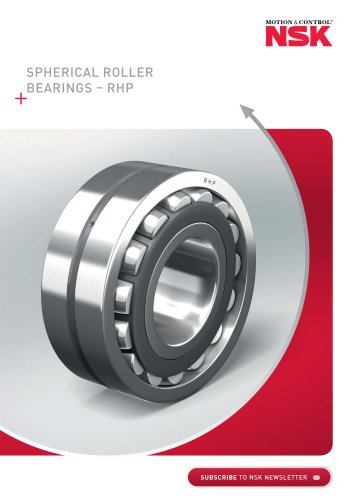

Technical Information Deep Groove Ball Brgs. Tech. Info. Angular Contact Ball Brgs. Cylindrical Roller Brgs. Full-Complement Cylindrical Roller Brgs. Tapered Roller Brgs. Spherical Roller Brgs. Thrust Brgs. Rolling Bearings For Steel Mills Steel Mills Triple-Ring Brgs. Crossed Roller Brgs. Application Drawings Index of Inch Design Tapered Roller Brgs. Special NSK Bearings And Related Equipment

Open the catalog to page 2

Introduction to NSK Large-Size Rolling Bearing Catalog (CAT. No. E125f) We want to thank you for your interest in this edition of our Large-Size Rolling Bearing Catalog. Recently, operating requirements for machines and other equipment that use rolling bearings have become increasingly severe and diversified. Accordingly, rolling bearings, which are highly important machine elements, must be designed to satisfy more and more stringent requirements for higher speeds, greater precision, higher reliability, and other challenging demands. We edited this Large-Size Rolling Bearing Catalog to...

Open the catalog to page 3

1. SELECTION OF BEARING SIZE 1.1 Bearing Life The various functions required of rolling bearings vary according to the bearing application. These functions must be performed for a prolonged period. Even if bearings are properly mounted and correctly operated, they will eventually fail to perform satisfactorily due to an increase in noise and vibration, loss of running accuracy, deterioration of grease, or fatigue flaking of the rolling surfaces. Bearing life, in the broad sense of the term, is the period during which bearings continue to operate and to satisfy their required functions. This...

Open the catalog to page 7

SELECTION OF BEARING SIZE Ball Bearings Roller Bearings Fig. 1.1 Bearing Speed and Speed Factor If rolling bearings are used at high temperature, the hardness of the bearing steel decreases. Consequently, the basic dynamic load rating, which depends on the physical properties of the material, also decreases. Therefore, the basic dynamic load rating should be adjusted for the higher temperature using the following equation: 1.2.3 Temperature Adjustment for Basic Dynamic Load Rating If the bearing load P and speed n are known, determine a fatigue life factor f h appropriate for the projected...

Open the catalog to page 8

1.2.4 Adjustment of Rating Fatigue Life As described previously, the basic equations for calculating the rating fatigue life are as follows: The life adjustment factor for reliability a 1 is listed in Table 1.3 for reliabilities higher than 90%. The life adjustment factor for special bearing property a 2 is greater than one because of improvements in bearing steel. NSK now uses vacuum degassed bearing steel, and the results of tests by NSK show that life is greatly improved when compared with earlier materials. The basic dynamic load ratings C r and C a listed in the bearing tables were...

Open the catalog to page 9

SELECTION OF BEARING SIZE 1.3 Calculation of Bearing Loads 1.3.2 Average of Fluctuating Load The loads applied on bearings generally include the weight of the body to be supported by the bearings, the weight of the revolving elements themselves, the transmission power of gears and belting, the load produced by the operation of the machine in which the bearings are used, etc. These loads can be theoretically calculated, but some of them are difficult to estimate. Therefore, it become necessary to correct the estimates using empirically derived data. When the load applied on bearings...

Open the catalog to page 10

Fig. 1.3 Incremental Load Variation Fig. 1.4 Simple Load Fluctuation 1.4 Dynamic Equivalent Load In some cases, the loads applied on bearings are purely radial or axial loads; however, in most cases, the loads are a combination of both. In addition, such loads usually fluctuate in both magnitude and direction. In such cases, the loads actually applied on bearings cannot be used for bearing life calculations; therefore, a hypothetical load that has a constant magnitude and passes through the center of the bearing, and will give the same bearing life that the bearing would attain under actual...

Open the catalog to page 11

SELECTION OF BEARING SIZE 1.5 Basic Static Load Ratings and Static Equivalent Loads 1.5.1 Basic Static Load Ratings When subjected to an excessive load or a strong shock load, rolling bearings may incur a local permanent deformation of the rolling elements and raceway surface if the elastic limit is exceeded. The nonelastic deformation increases in area and depth as the load increases, and when the load exceeds a certain limit, the smooth running of the bearing is impeded. The basic static load rating is defined as that static load which produces the following calculated contact stress at...

Open the catalog to page 12

2. BEARING TOLERANCES 2.1 Bearing Tolerance Standards Regarding bearing accuracy classes, besides ISO normal accuracy, as the accuracy improves there are Class 6X (for tapered roller bearings), Class 6, Class 5, and Class 4. The applicable accuracy classes for each bearing type and the correspondence of these classes are shown in Table 2.1. The tolerances for the boundary dimensions and running accuracy of rolling bearings are specified by ISO 492/199/582 (Accuracies of Rolling Bearings). Tolerances are specified for the following items: Dimensional Tolerances Items necessary to mount...

Open the catalog to page 13

BEARING TOLERANCES (Reference) Rough definitions of the items listed for Running Accuracy and their measuring methods are shown in Fig. 2.1, and they are described in detail in ISO 5593 (Rolling Bearings-Vocabulary) and JIS B 1515 (Rolling Bearings-Tolerances) and elsewhere. Supplementary Table Running Accuracy Inner Ring Outer Ring Dial Gauge Only the shaft or housing or central washer is to be rotated. Measuring Weight Measuring Weight Stops at two points for inside or outside surface Supporting pins at three points around circumference Fig. 2.1 Measuring Methods for Running Accuracy...

Open the catalog to page 14

Symbols for Boundary Dimensions and Running Accuracy d &ds &dmp Vdp Nominal bore diameter Deviation of a single bore diameter Single plane mean bore diameter deviation Bore diameter variation in a single radial plane Mean bore diameter variation Nominal outside diameter Deviation of a single outside diameter Single plane mean outside diameter deviation Outside diameter variation in a single radial plane Mean outside diameter variation Nominal inner ring width Deviation of a single inner ring width Inner ring width variation Nominal outer ring width Deviation of a single outer ring width...

Open the catalog to page 15All NSK Europe Ltd. catalogs and technical brochures

-

TECHNICAL REPORT

302 Pages

-

NEW BEARING DOCTOR

44 Pages

-

BEARING DESIGNATION SYSTEMS

48 Pages

-

ROLLING BEARINGS

704 Pages

-

HA / HS Series

1 Pages

-

NH and NS Series

1 Pages

-

K1

1 Pages

-

K1-L

1 Pages

-

DH/DS Series

1 Pages