Website:

Particle Measuring Systems

Website:

Particle Measuring Systems

Catalog excerpts

2 Channel Particle Sensor AVAILABLE WITH • Proven technology provides reliable and accurate data • Allows for immediate reaction to particle The Airnet® II particle sensor makes it easy and cost-effective to monitor your cleanroom. This particle sensor offers a small footprint, unparalleled performance, and data transmission capabilities while meeting the specification of ISO 21501-4 and ISO 14644-1:2015. Simple installation with versatile power options, the unit can be configured to accept distributed power from an in-house system, local power plug-in, or Power over Ethernet (PoE). Communication capabilities include Ethernet to interface with Pharmaceutical Net, Facility Net, or FacilityPro® software, Modbus communications, or optional 4-20 mA output. Data integrity is maintained through the use of a data queue feature that continues to gather data even if network communication is lost. To ensure proper flow conditions and vacuum system operation, these units incorporate a Dynamic Flow Sensing system that will alarm with a 15% change in flow conditions. For applications where decontamination using Vaporized Hydrogen Peroxide (VHP) is required, an optional VHP-compatible unit is available for a simple installation without complex valving (Airnet 510XR). Without measurement there is no control contamination events A low-cost solution for multipoint monitoring Interfaces with Facility Net, Pharmaceutical Net and FacilityPro Software for comprehensive management of cleanroom conditions A small footprint and flexible mounting options make it easy to install in cleanrooms and mini-environments A laser diode (LD) drastically reduces the need for maintenance and extends product lifecycle Automatic laser shutdown reduces laser failures Data queue maintains data integrity when communication is lost Optional 4-20 mA output for integration with existing systems to help you understand your environment and communicate with other systems Optional XR coating protects sensors against corrosive or oxidizing vapors in VHP sterilization processes F E AT U R E S • 2 channels • 0.5 and 5.0 µm size range, suitable for Pharmaceutical application • 1.0 CFM flow rate • Interfaces with Modbus communications and optional • • • • 4-20 mA output Chemical-resistant polycarbonate (PC) enclosure Low sample point cost Small enough for use in remote locations ISO14644-1:2015 Compliant Cleanroom monitoring Dedicated monitoring of critical locations Trend analysis Statistical process cont

Open the catalog to page 1

2 Channel Particle Sensor Size Range Flow Rate Counting Efficiency 50% ± 20% for most-sensitive channel. Meets ISO 21501-4 100% ± 10% at 1.5 to 2.0 times channel one size. Meets ISO 21501-4 Zero Count Laser Source Laser Classification Class 1 per EN60825 (Internally, a Class IIIB laser is used, per EN60825) Exterior Surface Sample Probe or Tubing 1/4” ID Flow System External vacuum 1/4” connection; automatic laser shutoff and alarm on 15% flow variation Vacuum Source > 11 in Hg (> 375 mBar) below atm pressure 24 VDC (0.5 A) 100 – 240 VAC ± 10%, 50 – 60 Hz, Power Supply (optional), or use of...

Open the catalog to page 2All Particle Measuring Systems catalogs and technical brochures

-

Pharmabilities

9 Pages

-

Data Analyst Software

2 Pages

-

BioCapt Single-Use 100 LPM

2 Pages

-

Lasair Pro

2 Pages

-

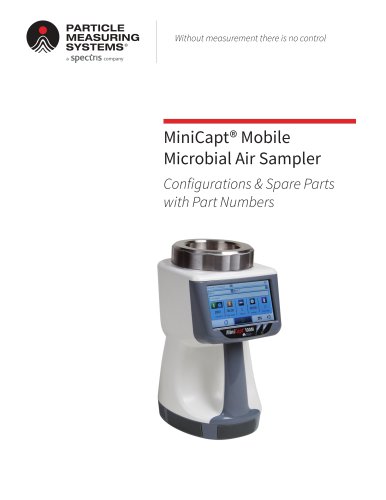

MiniCapt® Mobile

2 Pages

-

APSS-2000

2 Pages