Website:

Particle Measuring Systems

Website:

Particle Measuring Systems

Catalog excerpts

IsoAir® 310P Aerosol Particle Sensor BENEFITS Ensure compliance • Real-time particle monitoring gives quick notification of particle anomalies • Queues 3,000 samples in the event of computer system failure • Ethernet, Modbus and 4-20 mA outputs meet 21 CFR Part 11 regulations for data transmission security • Identifies breakdown in isolator protection Increase productivity • Interfaces with optional FacilityPro®, • • • • Pharmaceutical Net or Facility Net software for comprehensive management of the cleanroom Automatic paging allows rapid response to alarms Optional 4-20 mA inputs allow for integration of up to three environmental input sensors Easy to remove sensor simplifies calibration and service Validation documentation available • Complete monitor is easy to install • No central vacuum system needed • Rugged, chemically-resistant, easy-to-disinfect enclosure • Passivated stainless steel surface has well-defined microbial control characteristics The IsoAir 310P Aerosol Particle Sensor makes it easy to monitor air in remote locations or in areas with process restraints. Real-time particle monitoring gives quick notification of particle anomalies, detecting 0.5 and 5.0 µm for GMP and FDA compliance. A central vacuum is not needed to operate the particle sensor. It features a built in “low noise” blower with HEPA filtered exhaust. It has unparalleled performance in a chemical-resistant and easy-to-disinfect 316L external enclosure, and the passivated stainless steel surface has well defined microbial control characteristics. The clean, reliable internal pump lowers installation costs and the need for costly vacuum system connections. The instrument is available with a wide range of communications protocol such as Ethernet, Modbus, Wifi, and analog 4-20 mA for full compatibility with the existing monitoring system. Without measurement there is no control • Diode laser reduces maintenance requirements F E AT U R E S • Four standard channel sizes with 2-channel • • • • • • • Pharmaceutical mode Flow rate of 1.0 CFM Passivated 316L stainless steel enclosure Pump with HEPA filtered exhaust Automatic shut-off for capped probe Compliance with ISO 21501-4 and CE standards Two local LEDs for status and activity Ethernet or Modbus communications Pharmaceutical manufacturing area Isolator monitoring Cleanroom monitoring Aerospace and ind

Open the catalog to page 1

IsoAir® 310P Aerosol Particle Sensor 0.3, 0.5. 1.0 and 5.0 µm channels or can be set for two-channel mode: 0.5 and 5.0 µm Flow rate Sample probe/tubing 3/8’’ ID and up to two meters of 3/8’’ tubing can be connected to the inlet Vacuum source Internal reciprocal blower is quiet, cool running and long-lived, with no contaminating carbon vanes. Pump output is HEPA filtered, and discharged from the bottom of the enclosure. Automatic if pump fails, or if the system detects the sample probe is capped while the pump is on. Calibration materials used are traceable to the US National Institute of...

Open the catalog to page 2All Particle Measuring Systems catalogs and technical brochures

-

Pharmabilities

9 Pages

-

Data Analyst Software

2 Pages

-

BioCapt Single-Use 100 LPM

2 Pages

-

Lasair Pro

2 Pages

-

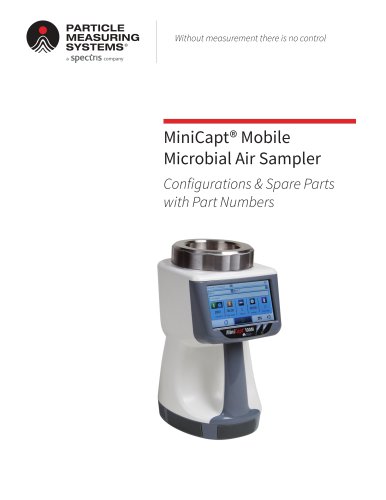

MiniCapt® Mobile

2 Pages

-

APSS-2000

2 Pages

-

Airnet® IIs

2 Pages