Website:

PerkinElmer

Website:

PerkinElmer

Group: PerkinElmer

Catalog excerpts

Simultaneous Thermal Analysis Authors Bruce Cassel PerkinElmer, Inc. Shelton, CT USA Jennifer McCurdy Vineyard Haven, MA USA Professor Charles Earnest Dept. of Chemistry, Berry College Mount Berry, GA, USA Porcelain Clay Analysis using the STA 8000 Simultaneous Thermal Analyzer In a process known for millennia, clay is heated to yellow heat where the components are transformed in a series of processes, as the “mud” is transformed into a useful vessel, or a beautiful piece of art. Whether a porcelain clay formulation is being used in the production of a commercial product, or an artistic creation, the ceramicist needs to ensure the quality of the finished product, and this depends in part upon the chemical and physical behavior of the formulation during the firing process. For example, in the firing of a porcelain clay object, such as shown above,1 the physical and chemical properties of the clay formulation determines whether the structure slumps as it is fired, whether there is cracking around sharp edges, and whether the final product is bright and translucent. So what can thermal analysis in general, and Simultaneous Thermal Analysis (STA) specifically, tell us about such a clay formulation and about the firing process?2,3,

Open the catalog to page 1

The initial endothermic weight loss process is due to the dehydroxylation of kaolinite to form metakaolinite by the process: 2 Al2Si2O5(OH)4 → 2 Al2Si2O7 + 4 H2O Figure 1. STA 8000 Simultaneous Thermal Analyzer. The Technique STA analyzes the weight change and transfer of energy to or from a sample while subjecting it to a controlled temperature and atmosphere. The STA 80005 (Figure 1) offered by PerkinElmer Inc., combines the wide temperature range of a differential thermal analyzer (DTA), with the sensitive weight measuring capability of a microgramcapable thermogravimetric analyzer...

Open the catalog to page 2

curves of most clays because it is eclipsed by the much stronger dehydroxylation endotherm. However, the amount of crystalline silica in a clay formulation can be estimated by cooling and re-running the sample after heating it sufficiently to allow the dehydroxylation reaction to go to completion. Figure 5. Thermal curves of SiO2 in window glass, unfired ceramic glaze, commercial silica and single quartz crystal. Detection of Tg of vitreous phases Figure 3. Three main components of porcelain clay run individually. Figure 4 shows the heat flow signal from heating silica (top curve) and a...

Open the catalog to page 3

Conclusions There are many ways the STA can be utilized to elucidate the processes taking place in the firing of clay. From the observed weight loss profile one can follow dehydroxylation and carbonate decomposition. The kinetics of these reactions can be quantified. Melting and crystallization can be detected from the heat flow data. Furthermore, the observed glass transition can indicate the temperature range where amorphous phases are softening. Figure 7. STA heat flow data of a translucent porcelain clay showing an apparent Tg on the reheat data. Is it possible to detect Tg in a ceramic...

Open the catalog to page 4All PerkinElmer catalogs and technical brochures

-

Cannabis Testing Solutions

12 Pages

-

ScanRI

2 Pages

-

Thermal Analysis

3 Pages

-

Ultra Clean Gas Filters

10 Pages

-

TurboMatrix

8 Pages

-

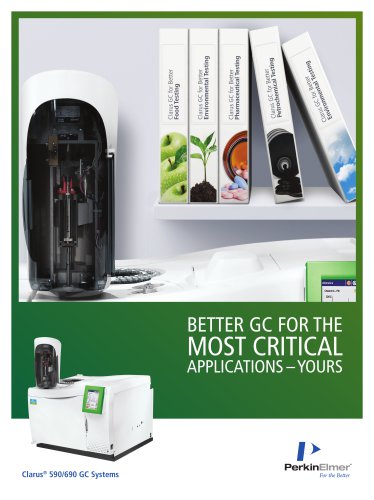

Clarus® 590/690 GC Systems

8 Pages

-

Titan MPS Microwave

4 Pages

-

PinAAcle 500

8 Pages

-

TurboMatrix

8 Pages

-

Flexar SQ 300 MS Brochure

8 Pages

-

Atomax Brochure

2 Pages

-

NexION 350 ICP-MS Brochure

12 Pages

-

Ultra Clean Gas Filters Catalog

10 Pages

-

AxION iQT GC/MS/MS

4 Pages

-

AxION 2 TOF

8 Pages

-

AxION DSA

8 Pages

-

AxION eDoor SQ

2 Pages

-

Flexar SQ 300 MS

8 Pages

-

Flexar PDA Plus Detector

2 Pages

-

NexION 300 ICP-MS Brochure

12 Pages

-

AAnalyst 200/400 Brochure

12 Pages

-

XRD Detector Series

2 Pages

Archived catalogs

-

FLEXAR™ Liquid Chromatography

12 Pages