Catalog excerpts

MicroSphere Refiner

Open the catalog to page 1

MSR TM - Microsphere Processing Technology The MSR™ MicroSphere Refiner is an all-in-one solution that combines all the individual stages required for microsphere processing, offering unique features and process designs. It addresses the major manufacturing challenges of microspheres and removes operator variability, reduces plant footprint and optimises capital investment. Microspheres or micro-particles are complex drug formulations that combine an Active Pharmaceutical Ingredient (API) with an FDA-approved polymer such as PLGA. Microsphere drugs enable the sustained release of APIs into...

Open the catalog to page 3

MSR TM - Microsphere Processing Technology Microsphere Drug Production: Redefined The MSR™ MicroSphere Refiner condenses multi-stage microsphere processing within a single, Current Good Manufacturing Practice (cGMP) instrument. It naturally maximises product recovery, batch repeatability and production flexibility of the microspheres as it can complete the following processes in one single system: Microsphere Classification/Filtration/De-watering Microsphere Aseptic Sampling Microsphere Washing Microsphere Aseptic Discharge/Product Recovery Microsphere Drying, including Freeze-Drying if...

Open the catalog to page 4

MSR TM - Microsphere Processing Technology Key Features 1: Pressure Vessel Filtration and drying occur within the MSR™ vessel, operating to secure maximum product discharge. Pressure capability results in efficient filtration. Vacuum proficiency optimises drying and, where more complex formulation is required, product freeze-drying can be used. 316L Stainless Steel construction Pressure Directives: PED, ASME “U” Stamp, SELO, etc. Temperature controlled, insulated base and side walls 2: Agitator The specially engineered blades are designed for distinct functionality, depending on the...

Open the catalog to page 5

MSR TM - Microsphere Processing Technology Various upstream methods exist for creating microspheres, but it is their downstream processing which is challenging using traditional methods. The MSR™ MicroSphere Refiner has revolutionised how effective microsphere processing is achieved using unique technology. De-watering and Size Classification Nascent microspheres typically undergo a solvent extraction in a buffer or quench tank. This highly diluted suspension transfers into the MSRTM vessel in a controlled manner for initial solid-liquid separation. The MSRTM vessel contains specially...

Open the catalog to page 6

MSR TM - Microsphere Processing Technology Product Drying Polymeric microspheres are dried to evaporate the final solvent traces and achieve final product quality. Various elements in the MSRTM can be temperature controlled, including the agitator. Cooling down the product throughout the process, avoids polymer degradation. The fully sealed vessel is put under low vacuum to help with solvent evaporation and reduces drying times. Agitating the product during drying ensures a homogeneous product batch. Freeze-Drying Where a more complex formulation is required, product freeze-drying can be...

Open the catalog to page 7

MSR TM - Microsphere Processing Technology Process Flexibility: The PSM If the vessel is the heart of the MSR™ technology, then Process Support Module (PSM) is the brain, allowing precise control and functionality. A Centralised Hub Cleanroom environments need to be controlled and maintained which is why the PSM is designed so utilities can connect to it via a single point of entry. Internal distribution pipework and diverting valves link utilities and process lines, for example: correct distribution of process nitrogen during filtration or drying steps. Monitoring and Control An array of...

Open the catalog to page 8

MSR TM - Microsphere Processing Technology Process Support Module Features Process Analytical Technology (PAT) Various additional instrumentation can be added for closer monitoring of the process. Processing Camera for visual inspection inside the vessel from a remote location Particle Size Analyser for product particle size distribution Dew Point Sensor for determining drying end points Conductivity Meters for optimising product washing cycles and/or CIP cycles Sterile Boundaries Polymeric microspheres, as injectable drugs, require sterile conditions. The PSM incorporates sterile...

Open the catalog to page 9

MSR TM - Microsphere Processing Technology A Plug & Play Solution By nature of the drugs being developed and manufactured in the MSR™, batch repeatability and traceability are critical. The MSR™ automation package has been developed and undergoes continuous improvement to support market and regulatory requirements including GAMP5 (Good Automated Manufacturing Practice, version 5 by ISPE) and 21 CFR Part 11 established by the US FDA for electronic records and Software Automation The MSR™ includes a software and automation package developed by PSL on a Siemens interface Architecture relies on...

Open the catalog to page 10

MSR TM - Microsphere Processing Technology Predictive Microsphere Scale-up Due to their characteristics and properties, polymeric microspheres have traditionally been known to be difficult to process for manufacturers – especially as the batch size gradually increases as part of the microsphere product development. The unique features of our MSR™ were developed following a Quality-byDesign (QbD) approach, taking into account the microspheres characteristics and process behaviour throughout scaling-up. LabMSR™ The LabMSR™ is a GLP piece of equipment developed to enable global drug...

Open the catalog to page 11

Taking your process further, together. For over 35 years, Powder Systems Limited (PSL) has been at the forefront of designing and engineering advanced technology to support process development. We are a globally recognised, award-winning business with expertise in pharmaceutical and chemical processing. Our focus is to help clients and partners address challenging manufacturing processes by providing fit-for-purpose solutions from our wide range of Microsphere Processing, Filtration and Drying ranges. w: powdersystems.com e: info@powdersystems.com t: +44 (0) 151 448 7700 Quality •...

Open the catalog to page 12All Powder Systems Limited (PSL) catalogs and technical brochures

-

GFD® Lab Filter Dryer

12 Pages

-

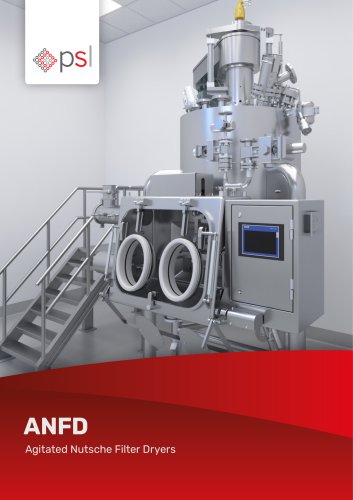

Agitated Nutsche Filter Dryers

12 Pages

-

GFD® Pilot Filter Dryer

12 Pages

-

SimpleFilter™

6 Pages