Catalog excerpts

PRODUCT OVERVIEW MILLING | SIEVING | ASSISTING SOLUTIONS FOR SAMPLE PREPARATION AND GRAIN SIZE ANALYSIS

Open the catalog to page 1

PRODUCT OVERVIEW THE NEW MIXER MILL MM 500 SERIES: EASY OPERATION COMBINED WITH EXCELLENT GRINDING RESULTS

Open the catalog to page 2

THE PIONEERS IN SAMPLE HOMOGENIZATION RETSCH – MORE THAN 100 YEARS OF INNOVATION Global market leader in the preparation and characterization of solids – quality „made in Germany“. The company was founded in 1915 by F. Kurt Retsch. A few years later he registered his first patent in grinding technology: a mortar grinder that became famous worldwide as the “RETSCH Mill”. This innovation replaced tiresome manual grinding with hand mortars which was the standard in laboratories at the time and earned RETSCH an excellent reputation in the international science and research community. With...

Open the catalog to page 3

PRODUCT OVERVIEW THE ART OF MILLING REPRODUCIBLE SAMPLE PREPARATION FOR RELIABLE ANALYSIS RESULTS A reliable and accurate analysis can only be guaranteed by reproducible sample preparation. The “art of milling and homogenization” is turning a laboratory sample into a representative part sample with homogeneous analytical fineness. For these tasks RETSCH offers a comprehensive range of the most modern mills and crushers for coarse, fine and ultra-fine size reduction of almost any material. To find the best suited mill for a specific application, the following should be considered in advance:...

Open the catalog to page 4

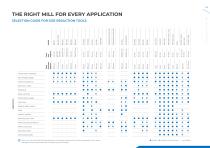

THE RIGHT MILL FOR EVERY APPLICATION Electronic waste Feed stuff Coal, coke Plastics, cable, rubber Leather, textiles Minerals, ores, rocks Pharmaceutical products Secondary fuels Please note: The achieved final fineness depends on the sample material and instrument configurations which means that different results may be obtained with apparently similar samples. Wood, bones, paper Chemical products Soil, sewage sludge

Open the catalog to page 5

PRODUCT OVERVIEW JAW CRUSHERS EFFICIENT PRELIMINARY AND FINE SIZE REDUCTION 120x90 This icon marks our product news Maximum feed size and final fineness This mill is suitable for cryogenic grinding Cyclone for improved material discharge and additional cooling Sieving Measuring range of sieve shakers / particle analyzers Suitable for wet sieving / for measuring suspensions Suitable for dry sieving / for measuring dry samples This instrument can be used with the EasySieve software I Compact, space-saving desktop model I Variable speed I Zero-point adjustment to compensate for wear I...

Open the catalog to page 6

PERFECT RESULTS FOR LABORATORIES AND PILOT PLANTS ROTOR MILLS Four different types of rotor mills are available for the pulverization of granular, soft, medium-hard or fibrous sample materials. All mills can be equipped with a cyclone for improved sample discharge and cooling. Depending on the model, the mills are suitable for the preparation of very small amounts but also for use in pilot plants. Ultra Centrifugal Mill ZM 300 Rotor Beater Mill SR 300 Cross Beater Mill SK 300 Cyclone Mill TWISTER I High final fineness up to 40 µm possible I Gentle, very fast pulverization I Wide speed range...

Open the catalog to page 7

PRODUCT OVERVIEW THE PROVEN GRINDOMIX GM 200 PRINCIPLE: ALSO SUITABLE FOR CRYOGENIC APPLICATIONS

Open the catalog to page 8

HOMOGENEITY IN THE SHORTEST TIME KNIFE MILLS The GRINDOMIX Knife Mills are perfectly suited for the quick and thorough homogenization of solid samples with high liquid, oil or fat content. Thanks to interval and reverse mode and a wide selection of accessories even difficult samples are completely homogenized in the GRINDOMIX mills. Knife Mill GRINDOMIX GM 200 Knife Mill GRINDOMIX GM 300 Vibratory Disc Mill RS 200 I Powerful homogenization of up to 700 ml sample material I Variable speed 2000 – 10000 rpm I Cryokit for cold grinding I Wide range of accessories available I Homogenization of...

Open the catalog to page 9

PRODUCT OVERVIEW BALL MILLS AND DRUM MILLS INNOVATIVE TECHNOLOGY THAT SETS GLOBAL STANDARDS THE FIRST CHOICE FOR FINE SIZE GRINDING RETSCH’s ball mill range is the widest in the world, offering optimum solutions for the pulverization of medium-hard, hard, brittle and fibrous samples with high energy input and short process times. The high-performance ball mill Emax and the planetary ball mills achieve high final finenesses with powerful performance, in many cases down to the nanometer range. They can be used for dry and wet grinding and are ideally suited for mechanical alloying and...

Open the catalog to page 10

PULVERIZING, MIXING, HOMOGENIZING XRD MILL AND MIXER MILLS The compact XRD-Mill McCrone is used for sample preparation to X-Ray diffraction. The mixer mills are specially designed for quick grinding, mixing and homogenization of small sample volumes, as well as for cell disruption or for mechanosynthesis. The CryoMill is the perfect choice for efficient pulverization and homogenization of elastic and temperature-sensitive sample XRD-Mill McCrone I Crystal lattice structure remains intact I Narrow, reproducible particle size distribution I Very compact desktop unit I Grinding speed...

Open the catalog to page 11

PRODUCT OVERVIEW RETSCH SIEVE SHAKERS AND TEST SIEVES FOR PRECISE PARTICLE SIZE ANALYSIS

Open the catalog to page 12

FOR THE PARTICLE SIZE DETERMINATION OF BULK MATERIALS THE PERFECT SIEVING MACHINE FOR EVERY MATERIAL RETSCH’s range of sieving machines not only covers a very wide measuring range, it also provides a suitable model for virtually any bulk material thanks to different sieving motions and sieve diameters. The instruments are used in Vibratory Sieve Shaker AS 200 basic Vibratory Sieve Shaker AS 200 digit cA Vibratory Sieve Shaker AS 200 control Vibratory Sieve Shaker AS 300 control Vibratory Sieve Shaker AS 450 basic I Basic model for dry & wet sieving of max. 3 kg sample I 3D throwing movement...

Open the catalog to page 13

PRODUCT OVERVIEW SAMPLE DIVIDERS AND FEEDERS ASSISTING – THE KEY TO GREATER EFFICIENCY IN THE LABORATORY From representative, reproducible sampling and sample division to uniform, continuous material feed; from efficient preparation of solid pellets for XRF analysis to rapid cleaning of grinding tools and test sieves to gentle sample drying: RETSCH offers a comprehensive range of useful assistants which enhance the performance of our mills and sieve shakers even further and ensure reliable analysis results. I Extremely high dividing accuracy for 6, 8 or 10 partial samples I Automatic...

Open the catalog to page 14All RETSCH catalogs and technical brochures

-

GENERAL CATALOGUE 2024

132 Pages

-

MM 500

2 Pages

-

TM500

2 Pages