Catalog excerpts

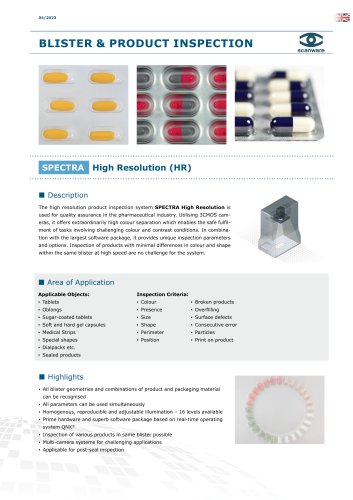

High Resolution (HR) ■ Description The high resolution product inspection system SPECTRA High Resolution is used for quality assurance in the pharmaceutical industry. Utilising 3CMOS cameras, it offers extraordinarily high colour separation which enables the safe fulfilment of tasks involving challenging colour and contrast conditions. In combination with the largest software package, it provides unique inspection parameters and options. Inspection of products with minimal differences in colour and shape within the same blister at high speed are no challenge for the system. ■ Area of Application Applicable Objects: ■ Tablets ■ Oblongs ■ Sugar-coated tablets ■ Soft and hard gel capsules ■ Medical Strips ■ Special shapes ■ Dialpacks etc. ■ Sealed products Inspection Criteria: ■ Colour ■ Presence ■ Size ■ Shape ■ Perimeter ■ Position ■ Broken products ■ Overfilling ■ Surface defects ■ Consecutive error ■ Particles ■ Print on product ■ Highlights ■ All blister geometries and combinations of product and packaging material can be recognised ■ All parameters can be used simultaneously ■ Homogenous, reproducible and adjustable illumination - 16 levels available ■ Prime hardware and superb software package based on real-time operating system QNX® ■ Inspection of various products in same blister possible ■ Multi-camera systems for challenging applications ■ A

Open the catalog to page 1

■ System The utilisation of the real-time operating system QNX® enables high-speed data transfers and high failure safety. Security is further enhanced thanks to other aspects of the system: The modular build enables the expansion for future and increasing requirements. Thus, the system is future-proof. The system is fully compliant to 21 CFR Part 11; format versions are saved separately. The memory contains up to 50 images which are the basis for an individual suggestion of parameter settings. This offers a higher level of security than standardised settings that the user needs to adjust...

Open the catalog to page 2

¢ Software The expert. Highest colour separation with elaborate op- Some of our extraordinary software features: ▪ Production report and format documentation Thanks to using QNX®, the software runs in real-time. ▪ Configurable machine stops All features can be used simultaneously – at high speed. ▪ Diagnosis of color, pocket, blister and error images ▪ Comprehensive Audit Trail ▪ Specialised algorithms such as x/y measurement, detection of upright objects – even the toughest tasks can be fulfilled The recognition of upright objects reduces product The use of x/y measurement is important for...

Open the catalog to page 3

Japan Quality Using multiple cameras, the product inspection according to Japan Quality standards is possible. SPECTRA High Resolution recognises diminutive optical errors and tiny particles. The software of SPECTRA High Resolution is equipped with a special algorithm for form recognition. Using multiple cameras, different products within one blister and a variety of shapes with minimal distinction can be recognised. The system's color separation power enables the distinction between colors that are the same to the naked eye. Thus, different colors in the same blister can be separated...

Open the catalog to page 4All Scanware Electronic catalogs and technical brochures

-

TRACK & TRACE

2 Pages

-

Codes (1DC / 2DC)

4 Pages

-

Tube 1DC

2 Pages

-

Print (HR)

4 Pages

-

Japan Quality (HR)

4 Pages

-

Contraceptives (HR)

2 Pages

-

Bulk

2 Pages

-

BLISTER & PRODUCT INSPECTION

4 Pages

-

Mobile Base Station (MB)

2 Pages

-

TRACK & TRACE

2 Pages

-

BLISTER & PRODUCT INSPECTION

4 Pages

-

PACKAGING INSPECTION

4 Pages