Website:

SCHMIDT + HAENSCH

Website:

SCHMIDT + HAENSCH

Catalog excerpts

LABORATORY PROCESS SOFT WARE AUTOMATION

Open the catalog to page 1

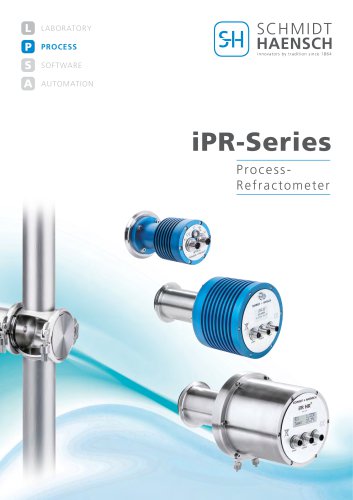

Yo u r e y e i n the pipe! Inline, immediate concentration monitoring directly within the process stream. Applications • Concentration monitoring • Product interface detection (product recovery) • Deviation from a nominal value (quality control) • Crystallization / powder or crystal dissolving monitoring • Dosage control (blending) • Impurity detection Inline Process Refractometers (iPR) from SCHMIDT+HAENSCH have been used successfully in a wide range of process monitoring applications for more than 35 years. Our iPRs continuously measure the refractive index and instantly determine the...

Open the catalog to page 2

Ap p li cat i on hi ghli ght s Inline Refractometer Food and beverage industry • Quality control of chocolate, coffee, yoghurt, soya milk, honey and other food additives • Dilution or evaporation process control in juice, jam, ketchup industries • Dealcoholisation process of beer • Payment system in the wine production (sugar content - Oechsle, Brix) • Process monitoring in the pectin prod. • Control of coffee and tea extraction process • CIP monitoring, product recovery and interface detection Sugar, starch, sweeteners • Brix measurement of: Cane sugar, beet sugar, starch, sugar, raw sugar...

Open the catalog to page 3

S m a r t h e a d s fo r smart solutions iPR inline sensors can be used as a stand-alone solution with integrated display or connected to a PLC. Using the integrated digital switches (up to 1 A), the iPRs can re-motely control pumps, valves as well as signals (e.g. visual, acoustic alarm). This feature allows a direct, real-time process control and simple automations (e.g. simple dosage systems) without an additional PLC. The iPR measuring heads can be combined with various process sensors such as O2, CO2, pH, turbidity or conductivity to an intelligent sensing station. To be resistant...

Open the catalog to page 4

Power supply 2 insulated 4 - 20 mA analog outputs 2 digital output switch (up to 1 A) 1 serial output RS232, alternativly RS485 or Measuring range Process temperature Wetted parts Sapphire; stainless steel, optional: PTFE Dimensions / Weight Measuring range Process temperature Wetted parts YAG; stainless steel, optional: PTFE Dimensions / Weight Allrounder in stainles steel & for higher temperature Measuring range Process temperature -10°C up to +100°C (with water cooling in- Wetted parts YAG; stainless steel, optional: PTFE Dimensions / Weight Model with highest resolution User...

Open the catalog to page 5

Mounting accessories for process integration Inline housing from SCHMIDT+HAENSCH are perfectly suitable for hygienic installations of processes in vessels or pipes. The VariVent joint system allows easy installation of iPR instruments through a plug-in and clamping method. The inline housing can be used with process pressure up to 10 bar. Some processes may require cleaning of the sensor face. SCHMIDT+HAENSCH offers an optional cleaning nozzle system or an ultrasonic cleaning system. For pipe size not shown in the table other combinations of bypass lines or reducers can be incorporated into...

Open the catalog to page 6

Inline housing VariVent / TriClamps ends For installation of an iPR in pipes with TriClamp connection Metric Outside diameter in accordance to DIN 11850, series II, DIN 11866, series A Nominal wide d Inch Outside diameter in accordance to ASME-BPE-a-2004, DIN 11866, series C Nominal wide d Inline housing APV / welded For the installation of an iPR in pipes by welding flange Metric Outside diameter in accordance to DIN 11850, series II, DIN 11866, series A Nominal wide d Prism cleaning options High pressure fluid or steam cleaning system Ultra sonic cleaning system Fluid/steam cleaning...

Open the catalog to page 7

90° pipe installation with high pressure fluid cleaning system Straight pipe installation Vessel mounting Straight pipe installation with ultrasonic cleaning system Schmidt + Haensch GmbH & Co. Waldstraße 80-81, 13403 Berlin, Germany Phone: + 49 (0 30) 417072-0, Fax: + 49 (0 30) 417072-99 © Schmidt + Haensch reserved all rights over texts and images Subject to modification without notice 06/18 Integration in automation system

Open the catalog to page 8All SCHMIDT + HAENSCH catalogs and technical brochures

-

VariRef

2 Pages

-

VariDens Series

2 Pages

-

VariPol Series

2 Pages

-

WLAN

2 Pages

-

ATR-L

2 Pages

-

Polartronic V

2 Pages

-

ATR-BR

2 Pages

-

iPR-Ex

2 Pages

-

Purity Analyser

3 Pages

-

On-line titration

3 Pages

-

On-Line Purity Analyser

4 Pages

-

iPR-Series

8 Pages

-

iPR B3

2 Pages

-

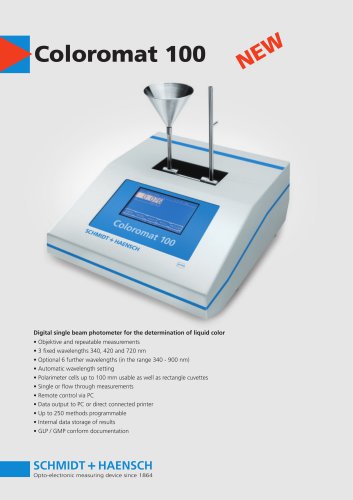

Coloromat 100

2 Pages

-

Saccharoflex 2020

2 Pages

-

AutoDosage

2 Pages

-

Saccharomat V

2 Pages

-

AutoFilt Z

2 Pages

-

DHR 95

2 Pages

-

Coloromat 100

2 Pages

-

iPR-Series

5 Pages

Archived catalogs

-

Aquisys 2008

2 Pages

-

SAMPLIFY P ©

2 Pages

-

ATR-P Touch

2 Pages

-

AutoFilt

2 Pages

-

Ash color turbidity analyser

2 Pages

-

On-line Ca++ analysator

3 Pages

-

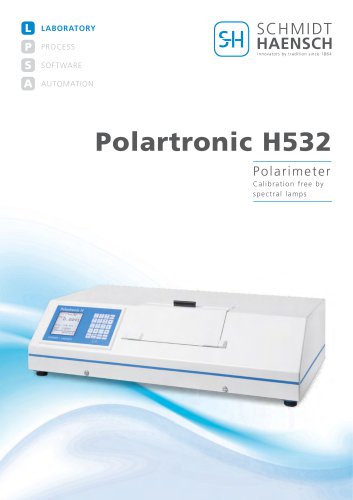

Polartronic H532

2 Pages

-

UniPol 2020

2 Pages

-

Polartronic N / M

2 Pages