Website:

Scotmas Group

Website:

Scotmas Group

Catalog excerpts

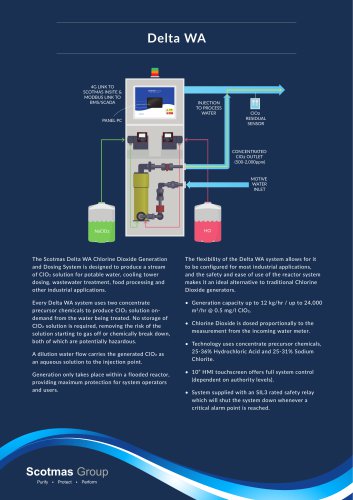

SCOTMAS DELTA WA Industrial and potable water treatment with ClO2 The Scotmas Delta WA Chlorine Dioxide Generation System is designed to produce a stream of ClO2 for water disinfection applications in: Industrial water treatment. Food and Beverage Production, Mollusc Control, BOD and COD reduction prior to discharge. Cooling tower water disinfection. Remove biofilm from all wet surfaces, improve cooling efficiency, reduce running costs. Wastewater treatment. Polishing of TSE before water recycling/reuse or discharge to the environment. Irrigation water disinfection. Protect crops by eliminating viruses, bacteria, fungi, nematodes, cysts and algae from irrigation water. Agricultural feed water disinfection. Provide animals with clean water and maximise their genetic potential. Potable water. Disinfect drinking water throughout the water treatment process. Every Delta WA system uses two concentrate precursor chemicals to produce ClO2 solution on-demand from the water being treated. No storage of ClO2 solution is required. A dilution water flow carries the generated ClO2 as an aqueous solution to the injection point. Generation only takes place within a flooded reactor, providing maximum protection for system operators and users. • Generation capacity up to 12 kg/hr / up to 24,000 m3/hr @ 0.5 mg/l ClO2. Chlorine Dioxide is dosed proportionally to the measurement from the incoming 4G LINK TO SCOTMAS INSITE & MODBUS LINK TO BMS/SCADA water meter. INJECTION TO PROCESS WATER Trained and authorised persons only to adjust this equipment Technology uses concentrate precursor chemicals, 25-36% Hydrochloric Acid and 25-31% Sodium Chlorite. 10” HMI touchscreen offers full system control (dependent on authority levels). DILUTION WATER FLOW System supplied with an SIL3 rated safety relay which will shut the system down whenever a critical alarm point is

Open the catalog to page 1

SAFETY: ClO2 is produced on demand only in a submerged reactor. Multiple safety interlocks control dosing and shut system down if parameters are breached. HIGH YIELD: Reactor efficiency >95% producing a stream of ClO2 solution and minimising chemical cost. RELIABILITY: Duty / standby auto switchover available. Scotmas Industrial Panel PC controller has been tested in multiple installations globally. LOW MAINTENANCE: Simple installation, set different operator authority levels as required. DOSING CONTROL: Residual Analyser PID dosing control maximises system flexibility and dosing accuracy....

Open the catalog to page 2All Scotmas Group catalogs and technical brochures

-

HEALTHCARE CASE STUDIES

4 Pages

-

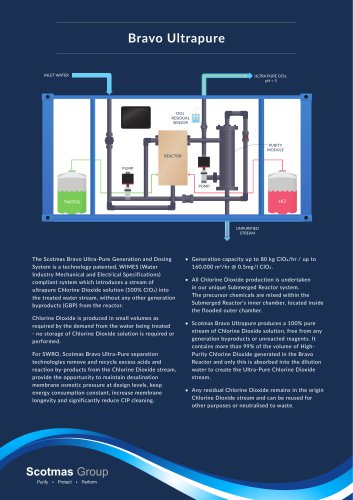

BRAVO ULTRA-PURE

2 Pages

-

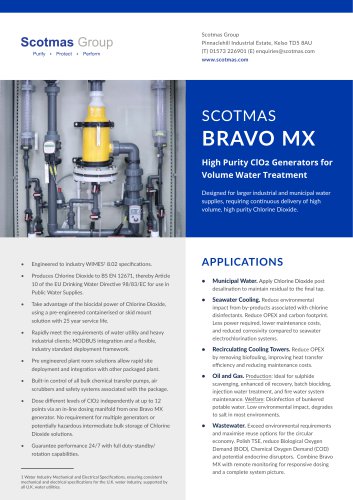

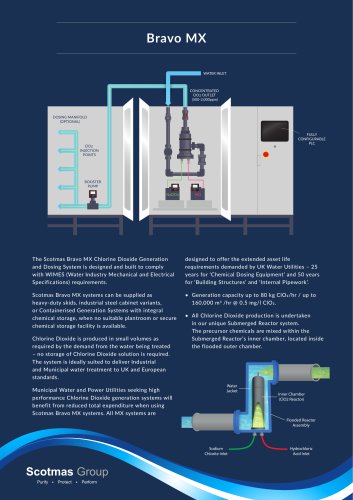

SCOTMAS BRAVO MX

2 Pages

-

Bravo Ultrapure

2 Pages

-

Bravo MX

2 Pages

-

Delta WA

2 Pages

-

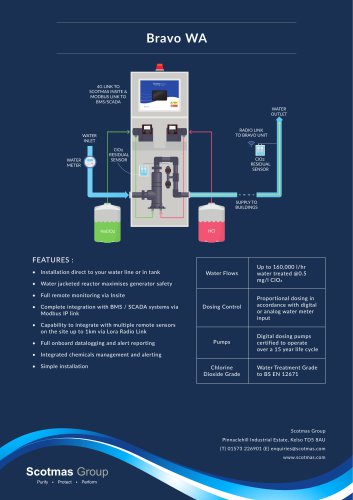

Bravo WA

1 Pages

-

Bravo Agriculture

1 Pages

-

Alpha R In Tank

1 Pages

-

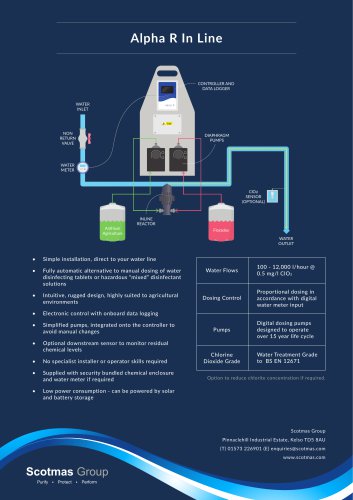

Alpha R In Line

1 Pages

-

CIDOX ® +

2 Pages

-

Cidox

1 Pages

-

Floradox

1 Pages