Catalog excerpts

Cellana Isolators Cell and Gene Therapy ATMPs

Open the catalog to page 1

Key Steps to achieve Best Process Quality in Cell and Gene Therapy Advanced therapy medicinal products (ATMPs) are fast-growing fields in modern medicine. ATMPs comprise innovative and sophisticated medicines to treat a v ariety f human disorders and genetic diseases. o It is critical to invest in manufacturing processes for these products to be compliant with cGMP regulations for the preparation and aseptic filling of sterile thera eutics for clinical and commercial use. p Choose Quality: Highest cGMP solution for ATMP products Biosafety Cabinet Open Cleanroom

Open the catalog to page 2

Explore an isolator for ATMP processes “My primary concern is protecting my process. Isolators provide a much higher level of contamination control. We partnered with SKAN due to their CGT process know ledge and in-depth experience with H2O2 with our sensitive biological products.” “Looking at life-cycle costs, it is a fact that the additional capital investment in isolators resulted in dramatic savings in facility and operational costs. It was easy to justify with a quick return on investment analysis.” “Cellana isolators are a green solution that save energy and adopt advanced...

Open the catalog to page 3

Adopt the best proven technology Integrate lab and process equipment into your ATMP solution Perform safe material transfers Everything you need to control and operate your ATMP process is here. Advanced process and lab equipment can be integrated directly into your Cellana isoator, creating a true process solution l within a fully compliant manufacturing platform. Aseptic transfer of supplies, equipment, buffers, media and most importantly, living cells, is a key function for your aseptic processing isolator. Choose the right transfer solution to address your limited time window, product...

Open the catalog to page 4

skanfog® automated decontamination Patented nanox® catalyst technology A fully automated and integrated decontamination system creates your compliant Grade A aseptic nvironment to protect your product, e personnel and process. skanfog® H2O2 d econtamination technology was developed by e xpert scientists with the fastest cycles in the i ndustry to maximise your production efficiency and quality. SKAN’s patented catalyst technology was developed to provide rapid cycle performance, but also eliminates waste streams and costly facility integration. Low-level sterilant residuals which can impact...

Open the catalog to page 5

Select the right isolator solution: Cellana The Cellana Isolator family represents SKAN’s 50+ years of experience in aseptic processing isolators. cGMP knowledge and process expertise are combined to safely provide patients with your Cell & Gene Therapy products.

Open the catalog to page 6

Key Features Modular w/ Flex chamber Integrated design Short delivery Key Features High flexibility Interchangeable modules Scalability and versatility Main Features and Benefits FDA ISO 5/EU Grade A aseptic environment with unidirectional airflow Integrated automated H2O2 decontamination validated with expert process guarantee and SKANalytix support Ultrafast decontamination transfer systems customised to your process 21 CFR Part 11 Compliant Controls and PC-based HMI with optional SCADA Integrated centrifuges, CO2 incubators and lab equipment from multiple leading vendors Optional...

Open the catalog to page 7

Apply the right solutions to your process Upstream Final Aseptic Filling

Open the catalog to page 8

Example: Mesenchymal Stem Cell preparation From cell thawing to cell harvesting and final downstream steps in Cellana-M Cell thawing Cell centrifugation Cell growth in CO2 incubator Cell seeding Cell pellet resuspension Cell harvesting and filling Cell growth in CO2 incubator CO2 Cell centrifugation Cell filtration Cell harvesting Cell pellet resuspension

Open the catalog to page 9

Example: CAR T-cell therapy production Step-by-step from aseptic leukapheresis bag transfer, gene editing and CAR T-cell separation to final cell formulation in a high-throughput Cellana-L isolator system. Leukapheresis Leukapheresis Cell collection and separation Cell collection and separation T-cell activation T-cell activation T-cell modification (viral vectors, electroporation) T-cell modification (viral vectors, electroporation)

Open the catalog to page 10

T-cell Expansion T-cell expansion CAR-expressing T-cell isolation CAR-expressing cell purification Final Cell Formulation Final Cell Formulation Infusion Infusion

Open the catalog to page 11

Implement Flexible Aseptic Filling SKAN provides a wide range of fully-integrated isolator-based aseptic filling solutions. Cellana is your one-stop solution for manual to highly automated filling, including robotic systems. Upstream Final Aseptic Filling

Open the catalog to page 12

Validate your process with Expert Support The scientific method is the only approach for successful qualification of cGMP processes. Quality must be implemented in the design phase (QbD). SKAN’s compliant regulatory strategy maintains your product quality at the highest level. We collaborate with our partners and share our ex erience to define the right isolator for your specific needs. p

Open the catalog to page 14

Utilise smart digitalisation solutions SKAN integrates digital solutions for your process control and automation needs

Open the catalog to page 15

SKAN Stein AG Rüchligstrasse 296 4332 Stein, T +41 62 873 18 41 info.stein@skan.ch SKAN Deutschland GmbH Nickrischer Straße 2 02827 Görlitz/Hagenwerder, Germany T +49 358 223 789 0, de.info@de.skan.ch SKAN US, Inc. 7409 ACC Blvd., Suite 200 Raleigh, NC 27617, USA, T +1 919 354 6380 US.Sales@us.skan.ch, www.skan.com SKAN Japan 5194-61 Katsuren-Haebaru Uruma-shi Okinawa 沖縄県 904-2311 Japan 日本 Tel +81 98 934 9922 JPSkan@skan.ch

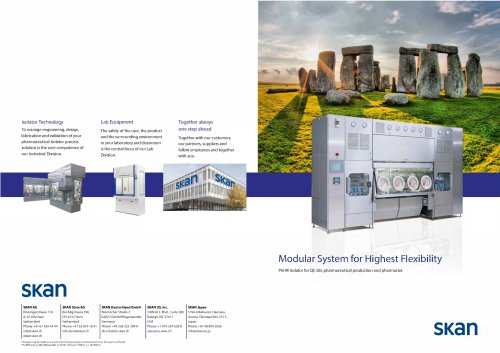

Open the catalog to page 16All Skan catalogs and technical brochures

-

Multipurpose isolator pure

7 Pages

Archived catalogs

-

Sterility testing

14 Pages

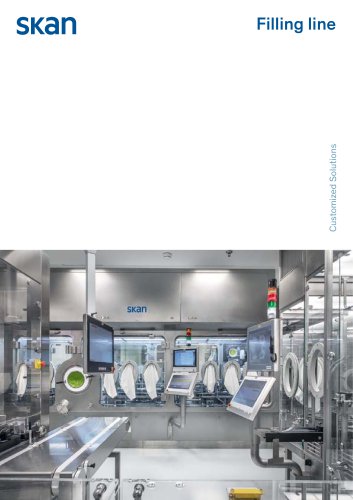

-

Filling line

11 Pages