Catalog excerpts

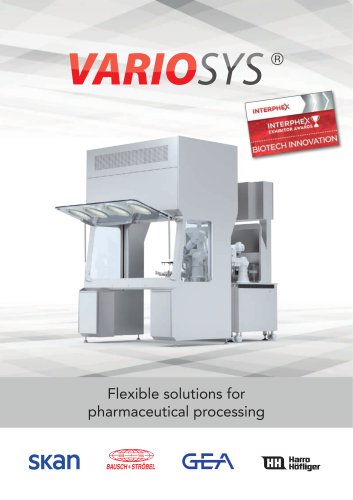

Flexible solutions for pharmaceutical processing

Open the catalog to page 1

CONTENT Information Discover VarioSys® 4 Fields of application 4 Benefits 5 Four partners – one system 6-7 Isolator 8-9 Process 1 Semi-automatic processing Dosing machines EDM Closing machines SVP+HVM Multifunctional workbench KCP Aseptic filling module for IV bags Process 2 Nest processing Modules for tub opening and denesting Module for RTU containers SFM Process 3 Processing containers in bulk 22-23 Module for ampoules AFV 24-25 Modules for vials KSF+KS 26-27 Process 4 Automatic vial processing with freeze drying 28-29 Freeze dryer 30-31 Process 5 Processing vials containing highly...

Open the catalog to page 2

Discover VarioSys® The innovative and highly flexible VarioSys® production system for biotech and pharmaceuticals is essentially a combination of two elements: an isolator made by SKAN and machine modules made by Bausch+Ströbel and Harro Höfliger. The system has been designed to provide utmost flexibility in the production of medications by exchanging modules. The machine modules are simply slotted into place on the “lock-and-key” principle and plugged in. Pharmaceutical production can be extended by adding a suitable freeze-dryer made by GEA. VarioSys® is suitable for a wide range of...

Open the catalog to page 4

Plug & Play Extendable modular design Modular design of the processing line Adaptable to various packaging materials GMP and FDA conforming machine design Processing toxic medications Space saving Time efficient

Open the catalog to page 5

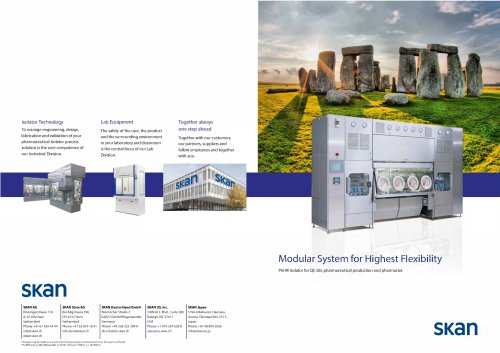

Four partners – one system Founded in 1968, SKAN AG holds today a leading position in the field of isolator technology for the pharmaceutical industry worldwide. Our major products include: various safety glove isolator and filling isolator for aseptic or/and highly active products, as well as complete validation/ qualification documentation and service execution. For 20 years we have been the leading manufacturer of isolator systems in the pharmaceutical sector. Harro Höfliger is specialized in the development of customer-oriented process and production solutions for pharmaceutical and...

Open the catalog to page 6

Information Providing the best technical and economical answers to the challenges presented by the world market. With this clearly defined company goal in mind, we design, build and sell packaging and production systems for the pharmaceutical and allied industries. From modest beginnings more than 50 years ago – with only four people – Bausch+Ströbel has developed into an international enterprise. It is now one of the leading manufacturers in pharmaceutical packaging. GEA is an expert in freeze drying technology – a partner that knows the requirements of the pharmaceutical and biotech...

Open the catalog to page 7

SKAN VarioSys Isolator (PSI-L 2.0) Isolator The isolator provides an aseptic environment for the VarioSys® system and thus reliably protects the operating personnel and the product. This solution is suitable for processing aseptic and/or highly active substances. The new version of the isolator impresses with the patented SKANFOG® Flow System, a cleaning-friendly design and a revised air processing concept. Highest process reliability is ensured by reliable cycles with lower consumption and, above all, a significantly reduced cycle time. Great variety of possible combinations Efficient...

Open the catalog to page 8

The newly designed SARA-XL with integrated SKANFOG® Flow technology is a safe and fast airlock for a short and gentle bio-decontamination process. The upgraded stainless-steel construction is also easy to clean. Due to its modular design, the airlock can be attached to any isolator configuration. Even when loaded, very short cycle times are possible. In addition, the principle of the single flow chamber in conjunction with the double HEPA filtered exhaust air ensure the highest level of process reliability SKANFOG® H2O2 micro-nebulization Controlling the microbial load within A/B cleanroom...

Open the catalog to page 9

Semi-automatic processing VarioSys® provides an ideal production environment – whether in galenics, in the lab or in small batch manufacturing. Equipped with semi-automatic machines, it can be used to fill a wide range of different containers with liquid and powder products very flexibly and efficiently. The system can easily be upgraded to a fully functional production line at any time. Quick decontamination SARA for material transfer Bench-top machine for simple and precise filling of all kinds of containers EDM Bench-top machine for closing vials with crimp or screw caps HVM Bench-top...

Open the catalog to page 10

Dosing machines EDM Bench-top machines for simple and precise filling of all kinds of containers. Unstable containers such as cartridges, syringes barrels and test tubes can also be processed easily using transport stands. Rotary piston pump Patented single-hose peristaltic pump ViscoTec rotary displacement pump for dosing highly viscous (up to 5.000.000 mPas), shear sensitive and abrasive products technology (self-priming and run empty function without product loss, only the last container may need to be rejected) Filling needle movement Vacuum-assisted dosing Automatic feedback adjustment...

Open the catalog to page 12

Closing machines SVP and HVM Machine type SVP Bench-top machine to close cartridges and syringes with plunger stoppers (type SVP). The stopper insertion depth and insertion speed can be freely selected. Gas-flushing during stopper insertion (option) Stopper insertion by vacuum (option) Technical Specifications SVP Plunger stoppers SVP for closing cartridges and syringes Bench-top machine for closing vials and cartridges with crimp caps or flip-off caps. Crimping speed and pressure as well as crimping tool lift are freely adjustable. Features: Rotation of containers during closing Central...

Open the catalog to page 13

Multifunctional workbench KCP 5105 Module for filling and closing containers. One up to three handling stations with a flexible design can be installed on this module. It is possible to transfer 1:1 the production parameters from and to fully automatic machines. Various dosing systems for liquid and powder products – rotary piston pump, patented single-hose peristaltic pump, time/pressure dosing system and auger dosing system Closing station for stoppers or similar inserts, crimp caps, screw caps In-process control 1 – 100 % Production parameters can be transferred to fully automatic...

Open the catalog to page 14All Skan catalogs and technical brochures

-

Multipurpose isolator pure

7 Pages

Archived catalogs

-

Cell and Gene Therapy ATMPs

16 Pages

-

Sterility testing

14 Pages

-

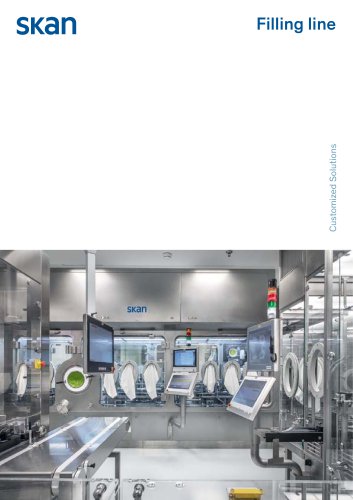

Filling line

11 Pages