Catalog excerpts

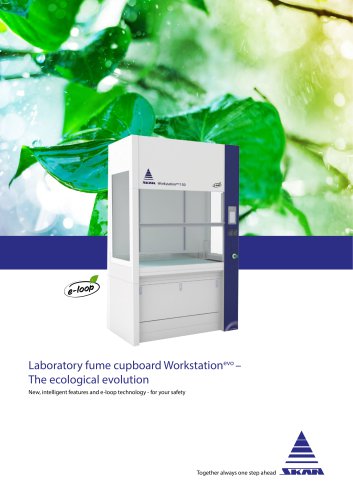

Laboratory fume cupboard Workstationevo – The ecological evolution New, intelligent features and e-loop technology - for your safety Together always one step ahead

Open the catalog to page 1

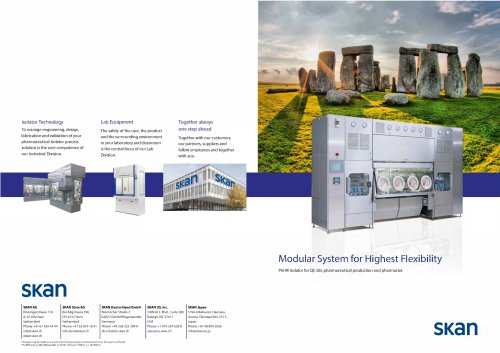

SKAN Pure Solutions SKAN Founded in 1968 as a trading company for Scandinavian Furthermore, we are able to offer integrated overall solu- laboratory equipment, which corresponds to today's SKAN tions. The focus is on the horizontal and vertical integration Pure Solutions division, SKAN is now the world market of our systems into building technology and solutions in leader in the field of isolator production for aseptic appli- the area of Data Intelligence as well as VR/AR and Digital One of our core competencies is the manufacture of pro- Currently, we employ around 800 people from over 40...

Open the catalog to page 2

flexibel wirtschaftlich sicher flexibel ökologisch sicher ergonomisch ökologisch wirtschaftlich Umgebungsschutz Laboratory fume cupboard Workstationevo Produktschutz Personenschutz UmgebungsProduktschutz schutz sicher laminar qualifizierbar Umgebungsschutz turbulent qualifizierbar Personal and environmental protection against chemicals, solvent vapours and active substances Low volume of exhaust air, limited ventilation capacity of the building Energy-saving & resource-saving No deposits in the outgoing air ducts The Workstation is a fume cupboard with partial air recirculation and an...

Open the catalog to page 3

The inflow air is drawn in from the environment, i.e. from the laboratory, through the front opening. The air curtain at the work opening prevents the contaminants from escaping. The fresh air mixes with the contaminated air from the work zone and is extracted directly to the filters through the 2 air intake grilles on the work surface. Cleaned and free of contaminants, the entire exhaust air first goes to the internal ventilation and then to the top section of the workstation. The volume flow is divided there: Half is extracted into the outgoing air of the building, the other half is...

Open the catalog to page 4

e-loop technology The “e” in e-loop stands both for economic and ecological. The SKAN development combines all technical measures for the cost-saving and resource-saving partial air recirculation principle of the Workstationevo. When working, you will not notice any difference in safety and ergonomics compared to conventional fume cupboards. The main differences lie in the unique air flow and the special filter technology. Compared to conventional fume cupboards, the amount of outgoing air and the energy used are reduced many times over. This expands the use of the building, saves costs and...

Open the catalog to page 5

Handling & settings The LCD touchscreen increases the ease of use significantly. Thanks to the clear menu navigation, the most important settings (such as the lighting in the work area) can be quickly changed and read. The Eco Mode further contributes to energy savings. Operating mode: Glass open, lights on, fan runs at normal speed. Energy costs A substantiated calculation of the operating costs shows the extensive savings potential in energy costs. Compared to a conventional laboratory fume cupboard, the annual expenditure is up to 70% lower. In this way, investment costs can be amortised...

Open the catalog to page 6

Outgoing air Up to 60% less outgoing air, saves energy and operating costs. Electric sliding front glass (option) With motion sensors for Eco Mode and anti-crush protection. Extraction at the source Efficient table extraction even of heavy vapours. Work surface Depending on the application, made of stainless steel, glass or plastic. Filter cartridge A variety of filters and filter combinations are available.

Open the catalog to page 7

e-loop For sustainable and cost-saving operation. Touchscreen For intuitive and easy operation. Filter saturation The degree of saturation of the activated carbon filter is shown on the display. Filter type Display of the type of filter used provides additional safety: Is my application compatible with the filter? Media fittings For media or additional power connections.

Open the catalog to page 8

Thanks to the integrated extraction and filter technology, the Workstationevo has a very wide range of uses and the safety when working with active or unknown substances increases significantly. For the correct removal of the contaminants, it is essential to check the work planned in the system carefully and to define the correct filters. Suitability Workstationevo Analytical (organic) chemistry Workstationevo Filter recommendation: Activated carbon Weighing tasks with active substances (Micro and semi-micro range Workstationevo Filter recommendation: HEPA, activated carbon, SafeChange...

Open the catalog to page 9

Filters and filter combinations The Workstationevo achieves its uniqueness not least through the use of filters and filter combinations. SKAN Pure Solutions works closely with the filter manufacturers. We will be pleased to advise you regarding the correct composition of your filter package; special mixtures of activated carbon filters are also possible. The regular replacement of the filters is also guaranteed by us. Activated carbon filter Solvent vapours and odours are effectively retained at the source. Activated carbon filters are available as standard for the following applications:...

Open the catalog to page 10

It has always been a strong point of SKAN Pure Solutions to equip and adapt the systems, be it laboratory fume cupboards or safety workbenches, according to the specific requirements of the user. The accessories for the Workstationevo offer a wide range of options. Media fittings Fittings that can be used for a wide variety of media: Nitrogen, oxygen, vacuum, compressed air, etc. Precision fittings Precision fittings for the following media are available for use in the Workstationevo: Nitrogen, argon, helium, compressed air, carbon dioxide, oxygen. The fittings are available for control...

Open the catalog to page 11

Sockets In addition to the external sockets on the control panel, there is also the option of equipping the interior with sockets. This simplifies the placement of equipment in the work area. Work surfaces Made of stainless steel, glass or plastic according to your requirements. The side glass panels are available as PET or glass versions. Electric sliding front glass Infrared crush protection / anti-pinch protection is integrated in the electric sliding front glass with built-in motion sensor for standby mode.

Open the catalog to page 12All Skan catalogs and technical brochures

-

Multipurpose isolator pure

7 Pages

Archived catalogs

-

Cell and Gene Therapy ATMPs

16 Pages

-

Sterility testing

14 Pages

-

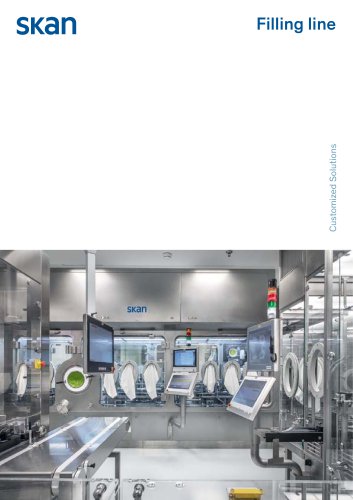

Filling line

11 Pages