Website:

Stratasys

Website:

Stratasys

Group: Stratasys

Catalog excerpts

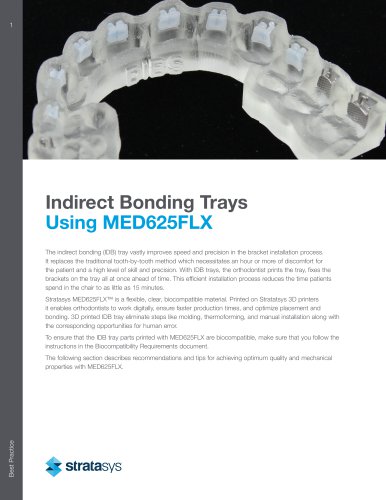

Indirect Bonding Trays Using MED625FLX The indirect bonding (IDB) tray vastly improves speed and precision in the bracket installation process. It replaces the traditional tooth-by-tooth method which necessitates an hour or more of discomfort for the patient and a high level of skill and precision. With IDB trays, the orthodontist prints the tray, fixes the brackets on the tray all at once ahead of time. This efficient installation process reduces the time patients spend in the chair to as little as 15 minutes. Stratasys MED625FLX™ is a flexible, clear, biocompatible material. Printed on Stratatsys 3D printers it enables orthodontists to work digitally, ensure faster production times, and optimize placement and bonding. 3D printed IDB tray eliminate steps like molding, thermoforming, and manual installation along with the corresponding opportunities for human error. To ensure that the IDB tray parts printed with MED625FLX are biocompatible, make sure that you follow the instructions in the Biocompatibility Requirements document. Best Practice The following section describes recommendations and tips for achieving optimum quality and mechanical properties with MED625FLX.

Open the catalog to page 1

1. Traditional Treatment Dental braces (also known as braces, orthodontic cases, or cases) are devices used in orthodontics to align and straighten teeth and help position them precisely to a person’s bite, while also aiming to improve dental health. Traditionally, the dental brackets are manually applied tooth by tooth by the orthodontist, making it highly dependent on the dentist’s expertise and precision. 2. Manually Produced IDB Tray Due to recent advancements in this area, a relatively new application was invented called an Indirect Bonding (IDB) tray. This new dental orthodontic...

Open the catalog to page 2

3 3. Semi-Digitally Manufactured IDB Tray The availability of 3D printing means IDB tray producers now have a means of partially digitizing the workflow of IDB tray production. Using CAD software, the clinic/lab can design a set-up arch, which includes digitally placed brackets. The technician digitally places brackets on the digital arch. Once printed, the technician can thermoform the IDB as in the manual IDB tray process above. 4. Direct-Printed 3D Printed IDB Tray With Stratasys’s new MED625FLX material and CAD design software, it is now possible to design a digital IDB tray, 3D print...

Open the catalog to page 3

4 IDB Tray Production 1. The traditional manually produced (non-3D printed) IDB tray production is a multi-phase process with many different steps that involves different tools to create an accurate appliance. It begins with creating a stone model of the patient’s teeth, usually done by a dental impression. This is followed by meticulously positioning each bracket on the model precisely where it should go on each tooth. This entire process is completed by several thermoforming steps. 2. The 3D printed IDB tray process is much faster and more accurate. If the orthodontist has an intraoral...

Open the catalog to page 4

5 Design Considerations When printing IDB tray parts from MED625FLX, part height along the Z-axis must not exceed the following measurements: • in HS (high speed) mode: 40 millimeters. in DM (digital material) mode: 18 millimeters This limitation is applicable to MED625FLX parts only. Therefore, whenever there are MED625FLX parts on the tray that exceed the measurements listed above, a warning message appears, and the print job is stopped. In DM mode, if the tray contains MED625FLX parts that are within the limitation and other parts (such as MED620) that are higher than 18 millimeters, the...

Open the catalog to page 5

6 Technical Specifications Software Requirements: 1. IDB Tray Design a. The 3Shape Indirect Bonding Module software is one of the most common options used by orthodontists to digitally design an IDB tray. The software allows automated bracket and wire placement, all done digitally on the scanned model. Once completed, the final IDB tray file can be exported as an STL file format. b. Besides 3Shape’s solution, there are other IDB tray design solutions, such as CAD BRACE SOFTWARE by FABDENT, ArcadLab by by ARCAD and others. NOTE: As with manually produced IDB trays, most designers will print...

Open the catalog to page 6

7 In this section the user can add Stratasys (Objet) printers by clicking on the Machine Library and choosing the Objet Connex 260/500 (mm) printer. Best Practice Once the printer is added, all STL files can be loaded and efficiently placed on the tray using the Automatic Placement à Geometry tab à Nest All Parts. The user can modify Part Interval and Platform Margin to try and utilize the tray.

Open the catalog to page 7

8 Once the printer is added, all STL files can be loaded and efficiently placed on the tray using the Automatic Placement à Geometry tab à Nest All Parts. The user can modify Part Interval and Platform Margin to try and utilize the tray. Using this method, the Objet 260/500 tray can be utilized to provide on average up to 23/60 IDB trays respectively, on a single tray, depending on the part sizes. Best Practice b. Netfabb® additive manufacturing can also provide automatic placement with even better nesting capabilities. Similar to Magics, the user can load Stratasys (Objet) printers by...

Open the catalog to page 8

And selecting Objet260/500 Connex from the Stratasys category - Once all parts are loaded to the tray, the user can click on Planar Packing button – And then on Pack Platform to nest all parts efficiently – Best Practice Regardless of the nesting method performed, it is important to note that for minimal support consumption, it is best to orient the IDB tray with teeth facing down as shown he

Open the catalog to page 9

Once the trays are properly nested, it is best to save the tray as a single STL file (and not as separated STLs). That will allow for easy import process on the Stratasys Objet260 Dental, Objet260 Dental Selection or Objet500 Dental Selection printers. Material Requirements MED625FLX is the recommended material for printing IDB trays due to its mechanical and biocompatible properties. It is a clear material with flexible mechanical properties. Biocompatibility Requirements MED625FLX is a biocompatible material like MED610™ and MED620, hence is suitable for prolonged skin contact (more than...

Open the catalog to page 10All Stratasys catalogs and technical brochures

-

J3 DentaJet 3D printer

2 Pages

-

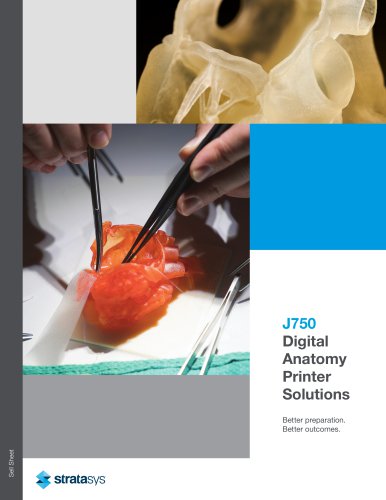

J750 Digital Anatomy

8 Pages

-

FDM Materials and Systems

12 Pages

-

F123 Series

4 Pages

-

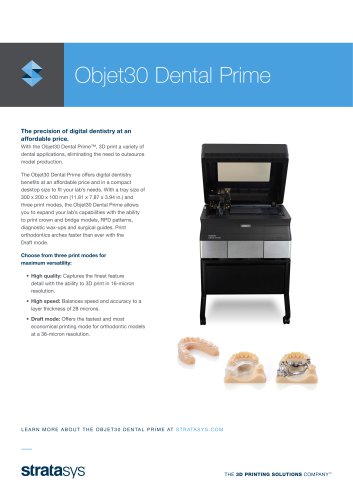

Objet30 Dental Prime

2 Pages

-

Fortus 450mc

8 Pages

-

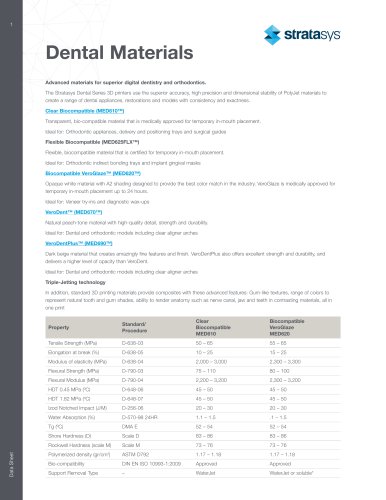

Dental Materials

2 Pages

-

Biocompatible Clear MED610

2 Pages

-

J5 MediJet

8 Pages

-

PolyJet Materials and Systems

16 Pages

-

Objet 260 Connex 3

2 Pages

-

J5 DentaJet

8 Pages

-

J720 Dental

4 Pages

-

J700 Dental

4 Pages