Catalog excerpts

All-electric Double-shot Injection Molding Machine All-electric Double-shot Injection Molding Machine

Open the catalog to page 1

Pursuing greater possibilities of parts with the Double-shot Enhancing product added-value by combining different materials Solutions made possible by two-material molding If you consider the vast range of material combinations available, the imaginable solutions offered by two-material molding are virtually endless. Our double-shot machines enable all kinds of molding possibilities and provide manufacturers the means to achieve high value-added production. Dimensional accuracy Combining different colors or grades of the same material or different materials entirely opens the door to new...

Open the catalog to page 2

Production efficiency spawned from the unique design Shorter setup time with integrated mold Thanks to an original design, our double-shot machine can easily mount large integrated mold. Compared to separate molds, integrated molds require considerably less time to set up, which translates into more efficient production operations. Example comparison of mold mounting Separate (two-type) mold Integrated mold Loading mold A Positioning Detaching mold B opening stopper Bolt tightening Bolt tightening Centrally located manifold * Mold B bolts temporary tightening Die height adjustment (mold...

Open the catalog to page 3

Fine-tune individual control before/after mold rotation Features designed for cycle time reduction Even with two perfectly identical two-material molds, there is actually a difference after rotating the mold. With our double-shot machine, molding inaccuracies of the sort have been improved by making it possible to individually control conditions before and after the rotation. Moreover, because torque is meticulously detected, molds are subjected to less stress, which relieves the worries of damaging expensive molds and allows to extend the maintenance interval. Our double-shot machine...

Open the catalog to page 4

Capability for a wide range of molding processes and special resins Multi-toggle is a mechanism that applies a low clamp force at the start of filling and then increases pressure as filling progresses. It improves gas release, prevents burrs from forming and lessens the frequency of mold cleaning. These benefits are especially appreciated in two-material molding where elastomers are often used. A low clamping force is applied at the start of filling to improve gas release. Clamp force is increased as filling progresses to prevent burrs. Particularly effective measure against elastomer gas...

Open the catalog to page 5

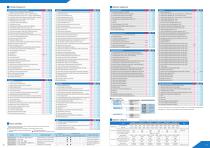

Main Specifications Item Clamp unit Clamp system Double toggle (5 points) Double toggle (5 points) Double toggle (5 points) Double toggle (5 points) Double toggle (5 points) Double toggle (5 points) Clearance between tie bars (WxH) Dimensions of rotary table (WxH) Daylight (When mold thickness extension 100 mm is selected) Mold opening stroke Platen speed max. Mold thickness (Min. - Max.) Locating ring diameter (Locating ring with inner diameter φ100 selected) Ejector system Ejector force (When ejector force power up is selected) Motor driven type (1 point) x 2 (When mold thickness...

Open the catalog to page 6

Standard Equipment Optional Equipment HS-CI Plasticizing and injection unit (FR common) DU-CI (230/280) 1. Standard SD screw assembly (Qpen nozzle, Nitride screw) ○ ○ 2. Injection program control function 5 stages / 2 stages (Switching) ○ ○ 3. Holding pressure program control function 4 stages / 2 stages (Switching) ○ ○ 4. Screw pull back function (After holding pressure end/After dosing is completed) ○ ○ 5. Digital display function of screw position (0.01 mm setting) ○ ○ 6. Holding pressure time 0.01sec setting ○ ○ 7. V-P switchover function (Pressure/Position) ○ ○ 8. Filling delay timer...

Open the catalog to page 7

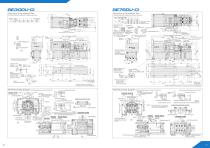

Piping for mold temperature control water of the mold reversal device. Uses at equal to or less than 120℃ (B-option) 【NOTE 1】 ※B-Option B064:Reversal table internal ejector rod detail view (1 4) : Tapped hole layout of take-out robot MOLD SPACE Mold mount surface 2×3PC ejector rods are provided CONNECTOR DETAIL MAKER: TYCO ELECTRONICS TYPE: D-3100S (1-178802-3) (The front and rear both) (The front and rear both) Width:17 【NOTES】 1) Since the ejector rod in the reversal unit does not return from operation,attention is required when removing the mold. Ejector plate return signal (2-lines)...

Open the catalog to page 8

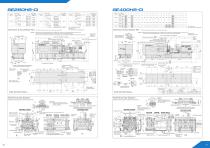

Rotating plate φ93 Water cooling jacket φ75 Power supply IVcable 80mm2 Leveling pads (A-option) Piping for mold temperature control water of the mold reversal device (B-option) 【NOTES】 3) When removing a mold, because reversal table internal ejector rod doesn't return operation. Ejector plate return signal connector (short plug) Ejector plate return signal (2 lines) STROKE MOLD SPACE STATIONARY PLATEN EJECTOR Tapped hole layout of take-out robot ※B-Option 236 B063-a:Piping for mold temperature control water of the mold reversal device 2-lines (Port size: 8-Rc3/8) Mold mounting...

Open the catalog to page 9

OA:Open exclusive type OR:Open type NR:Needle valve changeable type (Maintenance) At plasticizing unit turning 2) Max opening stroke changes from into 480mm and daylight changes into 1040mm when B088 ejector unit with brake is selected. 80-M16 Screw, depth30 Ejector plate return signal (2 lines) C Hopper mounting surface Cooling water jacket Supply Rc1/2 FL.+※252 Mold mounting surface Tapped hole layout of take-out robot ※B-Option 45 45 45 45 B063-b: 45 Piping for mold temperature control 22.5 water of the mold reversal device 4-lines (Port size: 16-Rc3/8) Safety door 8-M8 Screw,...

Open the catalog to page 10All Sumitomo Heavy Industries catalogs and technical brochures

-

Vertical

8 Pages

-

Packaging Series

10 Pages

-

SE-EV-A-SHR

4 Pages

-

iM18E

4 Pages