Catalog excerpts

IGH Heat Recovery Ventilation Unit

Open the catalog to page 1

IGH IGH has been designed to provide energy saving by recovery through heat energy exchangers. IGH is used in order to increase the quality of interior air in environments such as office, café, dormitory and class. Exhausting the dirty and moist air and recovering the heat energy in interior environments in residences such as bathrooms and kitchen, where the temperature is higher, while providing fresh conditioned air with the help of the recovered heat to the environments such as bedroom or living room, where more oxygen is required. 1. Casing All of the casing has been produced of...

Open the catalog to page 2

IGH 5. Filters Easily accessible and cleanable G2 class synthetic fiber based filters are used. There are filters at both the fresh air and the exhaust air inlets. Thus, both the conditioned particles in the air are hold and plate type heat exchangers are protected. 6. Electrical Heater and Heater Control (Optional) Depending on the place of use and the need, the electrical heaters can be provided in order to be connected to the fresh air discharges of the Heat Recovery ventilation units with a different size and capacity for each model itself. The resistances have been certified with the...

Open the catalog to page 3

IGH Standard Heat Recovery Ventilation Unit There is no electrical heater inside the standard device and no panel and control equipment to be used to use this heater. There is a standard speed switch mounted onto the device which enables the fans to be switched on and off and to be set at low, medium or high cycle. This switch is set to the required setting and thus an air flow as needed has been obtained. One of the basic properties of the device is to provide for the recovery of some of the energy when discharging the inside environment air, depending on interior and outside weather...

Open the catalog to page 4

IGH Control Equipments; • Differential Pressure Switch • Temperature Sensor • Control Panel • Control Card In addition to control equipment, the device needs a control panel, which is located on the body and an auxiliary stage panel, which is located on the heater. These panels are used to drive the resistances and to control the fans and in addition to these procedures, the safety measures are also taken with the control equipment. Main Purpose of Control Equipments; 1. Differential Pressure Switch: Cuts the energy of the heater in case of possible motor malfunctions. 2. Temperature...

Open the catalog to page 6

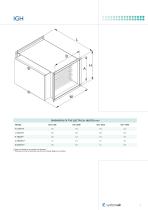

DIMENSIONS OF THE ELECTRICAL HEATER (mm) ^ Flange and electricity box are included in the dimensions. ^* Dimensions are of the air intersection inside the duct. Connection flanges are not included.

Open the catalog to page 7

Systemair - Sweden Industrivägen 3-SE 739 30 Skinnskatteberg / Sweden Tel : +46 222 440 00 Fax : +46 222 441 00 Systemair - Turkey Ömerli Mah. İhsangazi Sok. Hadımköy Yolu No: 28 Hadımköy / Arnavutköy / İstanbul / Turkey Tel : +90 212 623 22 10 Fax : +90 212 623 22 15 exportsales@systemairhsk.com.tr www.systemair.com.tr www.systemair.com

Open the catalog to page 8All Systemair HSK catalogs and technical brochures

-

AQWL/AQWH/AQWR 1404 to 2406

48 Pages

-

VLS/VLH/VLR 524 to 1204 NEW

52 Pages

-

Kälte- und Klimasysteme

208 Pages

-

Fan Coil

16 Pages

-

Water Source Heat Pump

8 Pages

-

Axial Heating Unit

8 Pages

-

High Pressure Fan Coil Units

8 Pages

-

Blueline

8 Pages

Archived catalogs

-

Fan Coil - 2014

8 Pages

-

CEILING TYPE

4 Pages

-

POOLLINE AIR HANDLING UNIT

4 Pages

-

MEDILINE PACKAGE HYGIENE

8 Pages

-

hsk

72 Pages

-

hygienline

8 Pages

-

Flexine catalog

12 Pages

-

blueline catalog

8 Pages