Catalog excerpts

Volume Flow Precision Tubing Flowsensors For Use With TS410 Flow Modules Measure volume flow in most non-aerated liquids including saline, buffer solutions, blood, water & even diesel fuel, with high resolution and low zero offset. Choose Clamp-on or Inline to match your flow circuit requirements. ME-PXL Clamp-on Flowsensors • Non-contact Clamp-on Sensors do not break circuit sterility • Preclinical and medical flow apparatus design • Small diameter Sensors for industrial use Innovative transit-time technology revolutionized blood flow measurement in medical tubing applications with these Flowsensors that clip onto the outside of flexible tubing to measure the flow within. They have become the standard for OEM medical design and preclinical extracorporeal use by providing non-invasive measurement with high accuracy and stability. Measurements are reliable even in challenging electromagnetic environments. The easy clip-on operation of the PXL Flowsensors also make these Sensors ideal for industrial flow measurement applications when process testing must quick, repeatable and applied to multiple circuits without flow interruption. Unlike large diameter industrial flow measurement devices, Transonic® provides high resolution Clamp-on Sensors for small diameter, to 1/8” OD, tubings. ME-PXN Inline Flowsensors • Measure flow over a wide dynamic range • Flexibility for tubing circuits that may vary or are still in the design phase • Highest sensitivity Sensors for low flow applications PXN Inline Flowsensors utilize a scheme of ultrasonic illumination that makes it possible to manufacture a flow-through Sensor with a smooth, cylindrical interior without compromising measurement accuracy. These Flowsensors offer more flexibility over Clamp-on Sensors as measurement calibration doesn’t depend on the type and exact size of tubing on which they are used. Small diameter PXN Inlines are ideal for low flow isolated heart or perfused organ studies.

Open the catalog to page 1

Volume Flow Calibration is dependent on tubing material, wall thickness, ultrasound velocity of liquid flowing through the tube & temperature. 1. Resolution represents the smallest detectable flow change at 0.1 Hz filter (average flow output). 2. Stated system accuracy specifications apply to PXL Flowsensors with TS410 Flow Modules. (a) Absolute accuracy is comprised APPLICATIONS • Artificial Heart & VAD Performance • Medical Device & Pump Engineering • Manufacturing & Compliance Flow Testing of zero stability, resolution and linearity effects. Stated values apply when flow rate is greater...

Open the catalog to page 2

PXN Inline Flowsensors splice into laboratory tubing and measure volumetric flow of blood and other fluids. They offer the most flexibility for flow measurement in circuits where tubing requirements have not been formalized. The four-transducer Sensor design offers precise and accurate flow measurement for low or high flow rates, steady state or pulsatile flows. Flow resolution is scaled to Sensor size, and flow is measured accurately across the Sensor's full dynamic range with little effect from turbulence. The Sensor's smooth round flow channel is easy to clean and does not trap air...

Open the catalog to page 3

Size Fluid/Temperature + Flow Rate Calibration Codes Up to four per Flowsensor Example: ME4PXN - BL37 SF - KR37 SF - FX37 LF, calibrated for 3 different uses: • Blood at 37°C at standard flow rate • Krebs at 37°C at standard flow rate • Custom fluid at 37°C at low flow rate FLOW RANGE 1. Glycerine calibration is custom for 1PXN-3PXN 2. All custom requirements (X) incur an extra charge How to Order a Flowsensor 1. ME- indicates compatibility with TS410 Flow Modules. 2. Determine if a PXN Inline or PXL Clamp-on Flowsensor is better for your application. a. If PXN Inline, choose the Sensor...

Open the catalog to page 4

Catalog #: ME PXL - - - - Size Suffix if Fluid/Temperature + Flow Rate Calibration Codes Metric OD Up to four per Flowsensor Tubing: Specify type and size (ID x wall x OD) Example: ME6PXL - BL37 SF - H2023 LF is for 3/8" OD tubing, calibrated for 2 uses: • Blood at 37° C at Standard Flow Rates on Tygon ND 100-65 (1/4" ID x 1/16" wall) • Water at 23° C at Low Flow Rates on Tygon E-3603 (1/4" ID x 1/16" wall) 1. In sizes 2-3PXL ratio of tubing wall thickness to OD must not exceed 1:5 for PVC; 1:3 for silicone 2. A= Tygon E-3603, B= Tygon ND 100-65 FLUID / TEMPERATURE CALIBRATION...

Open the catalog to page 5

Volume Flow CLEANING & STERILIZATION Transonic® Tubing Flowsensors may be cleaned with a solution of mild soap and warm water (<55ºC). The inside of PXN Flowsensors may be cleaned with a soft brush. Care should be taken to avoid scratching the inside surface of the tube. Common mild cleaning agents such as gluteraldehyde and OPA are acceptable to use; harsh disinfectants are not. Do not use alcohol to clean small 1 - 3PXN Sensors. Both PXL Clamp-on and PXN Inline Tubing Sensors may be sterilized by EtO gas. CUSTOMER SERVICE Contact your local distributor or sales representative for...

Open the catalog to page 6All Transonic catalogs and technical brochures

-

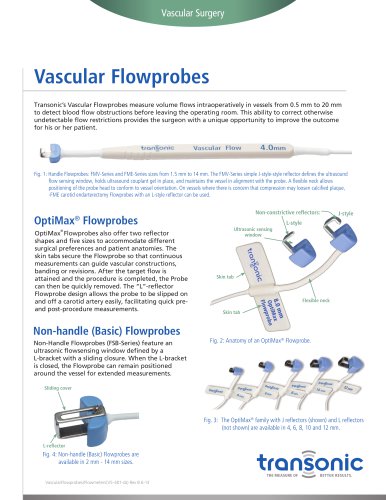

Vascular Flowprobes

2 Pages

-

Cardiac Surgery Flowprobes

2 Pages

-

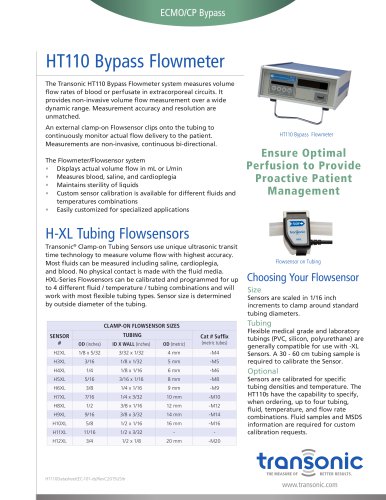

ECMO/CP Bypass

1 Pages

-

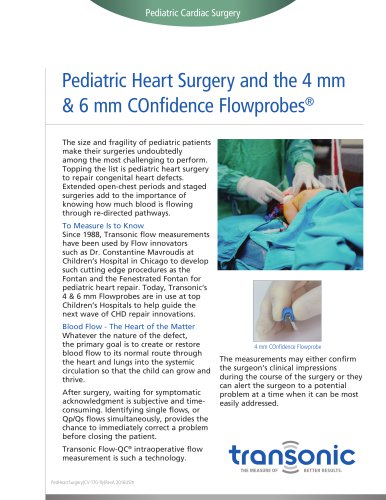

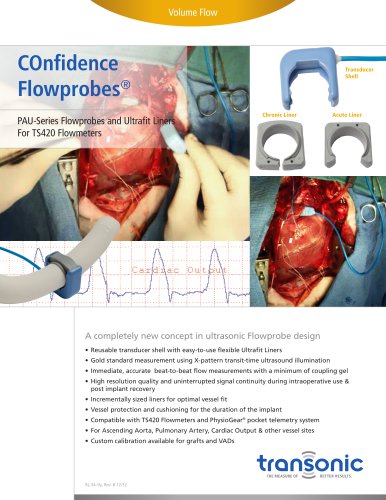

COnfidence Flowprobes

2 Pages

-

AureFlo & Optima

3 Pages