Catalog excerpts

INTEGRITY AND WIN-WIN BEYOND SELF # WITH YOU HAND IN HAND TO CREATEABETTER FUTURE JNBAN Belt Vacuum Drying (EVD) is a method of continuously distributing liquid raw materials on a canveyar belt under vacuum condilions, WENZHOU JINBANG LIGHT IND MACHINERY CO.,LTD No0.420, 23rd Road, 6th Binhai Road, Binhai Park, Longwan District, Wenzhou city, Zhejiang Province Enter the aMelal website

Open the catalog to page 1

2005 Set up a major science and technology project of Zhejiang Science and Technology Department. The product has obvious effect of environmental protection and energy saving in the practical application of pharmaceutical field. The unit design 2006 The company participated in the "11th Five-Year Plan" National Science Founded in Wenzhou, China, the company has become a professional enterprise engaged in the production and Traditional Chinese Medicine Equipment and Key Technologies (2006BADIOBAD8)". The company became a national high-tech enterprise. have become Company's product BVD has...

Open the catalog to page 2

Product features and description JNBAN Belt Vacuum belt under vacuum temperature drying method. quality final product. conditions. The materials are dried with the During the whole drying process, the extract is in a vacuum, plate, and then cooled, embrittled and pulverized. A low Since the material is gradually of time, the particles obtained temperature extent and at the same time, there are micropores inside from the microscopic structure. directly pulverizing to the required particle size, the flowability of the particles is very good, or filled with mash, fast solubility. Belt Vacuum...

Open the catalog to page 3

Belt vacuum dryer working principle Vacuum belt drying technology has a wide range of applications and materials heat high viscosity, easy belt shortcomings of too dry and too dense spray drying powder. addition, belt drying, feed rate, material thickness, drying environmental viscosity are also fully tested. At this point, belt vacuum high dryers are far superior to spray dryers. Series vacuum series vacuum belt drying unit overview. belt drying that Wenzhou Light Industry Machinery Co., Ltd. has successfully developed in recent years. patents in the field of vacuum manufacturer equipment...

Open the catalog to page 4

Vacuum belt dryer principle Based on the principle of humanized design: “the main body adopts thermal insulation measures to keep the working temperature of the equipment operating environment and the temperature within a suitable range. The inside and outside of the equipment are designed with corresponding detection ‘channels to facilitate daily maintenance and ~ maintenance. | Using digital integrated manufacturing technology, control during dynamic vacuum drying it can be adjusted freely online cleaning methods, can carry out all-round cleaning without thorough and fast, in line with...

Open the catalog to page 5

Using superheated water heating method, the energy consumption is 10% lower than other manufacturers at the same capacity. Using superheated water heating method eliminates the loss of the active component of the material, does not change the original color of the material, and no coke chip solubility is better. Track deviation correction adopts digital online automatic deviation correction technology (national invention patent). The first belt vacuum dryer Its high layer spacing is to meet the drying of various kinds of materials and can effectively through the foaming dry material to...

Open the catalog to page 6

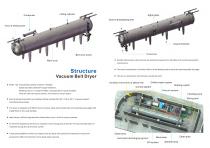

Lifting cylinder Sight glass Door atdischarging side Door at feeding side Supporting feet Belt drive motor ® Main body Double maintenance channels are set inside the equipment to facilitate and overhaul equipment maintenance. Structure Vacuum Belt Dryer The main engine barrel is inclined 100mm to the feeding end to solve the cleaning water drainage. Thereis no demand for lubricating oil inside the dryer. Auxiliary machinery in yellow line inside diameter 2500mm=x length Heating system Control system Vacuum system Heating area is 115 square meters. Cooling area is 9 square meters. Total dry...

Open the catalog to page 7

Heating system Feeding system Servo motor Heating system---Invention Feed system has 2 units of 2000 L concentrated extract cans. Heating plate Structure Extractum and auxiliary materials * Set 3 hot water heating unit and a district cooling unit, with use vacuum filling function. a buffer tank. * Constant pressure system, liquid level and temperature Anchor stirred structure of feeding tank has the functions of extractum monitoring device. mixing with auxiliary materials, which = Pressure reducing valve, steam trap adopts Spisharke, can adapt to many kinds of dry material. The temperature...

Open the catalog to page 8

* The heating temperature range of each section is precisely adjustable from 30°C to 135°C, which can adapt to the ying, oF varus iajeeilG, Comparison of heat transfer efficiency = Temperature uniformity: ensure inlet and outlet temperature difference +1.5°C. laverage temperature) = The pressure fluctuation in Party A's steam pipe network will not affect the temperature uniformity of the system. = The heating plate is manufactured according to GB150 "Pressure Vessel", and the testing water pressure is 1.0Mpa. less than 1.5mm during use. = The heating plate adopts zigzag type passage...

Open the catalog to page 9

It adopts two roots pump and 2 sets of water ring vacuum pump, which is level 3 configuration, properties, it ensures the production process of vacuum material can achieve the ideal state of evaporation. Condense the water vapour evaporated from the liquid material Powered water ring pump start at the same time when the device starts to work. After the two work vacuum degree reaching the set value, of which one water ring pump automatically switch to standby mode, the vacuum of the main engine can reach 1000Pa within 25 minutes. It has equipped with closed-circuit circulating water cooling...

Open the catalog to page 10

Chilled water system cooling section It's equipped with automatic constant temperature, high pressure protection, low pressure protection, electric current protection, Phase order protection, open phase protection, overload protection, high temperature lack of water protection, Exhaust protection. The operating state of the refrigeration unit is automatic adjustment. Compressor power classification energy consumption Track deviation correction system— Invention Patent NumberZL200710070502.1 Track deviation correction adopts digital online axial(real-time) automatic deviation correction...

Open the catalog to page 11