Catalog excerpts

Modern Cementing Technique Biomet Bone Cement R, Refobacin® Bone Cement R, and ClearMix™ Vacuum Mixing System Your progress. Our promise?

Open the catalog to page 1

Modern Cementing Technique Knee (MCT Knee) addresses implant loosening and the objective is to provide long term implant stability in knee arthroplasty. It is based on scientific data,1-26* findings by Zimmer Biomet27 and evidence-based techniques documented in the Swedish Hip Arthroplasty Register.1,2 The crucial factors in knee arthroplasty to achieve long term implant stability are to secure a strong bond and optimal interfaces, both between implant-cement and cement-bone. Implant-Cement Interface Bone Cement Cement-Bone Interface Implant-Cement Interface • Deliver the cement with a...

Open the catalog to page 2

Help to secure a strong bond and optimal interfaces between Implant-Cement and Cement-Bone

Open the catalog to page 3

4 | Modern Cementing Technique Bone Bed Preparation Cleanse all cement-receiving bone surfaces thoroughly using high pressure pulse lavage of the entire resected bone surface in order to ensure solid cement fixation.29-31 Clean repeatedly until clear fluid is received in the return line to reduce the amount of debris, blood, bacteria and fat.29-31 Tibia In sclerotic bone, supplementary anchorage holes may increase the contact area between bone and cement, providing enhanced fixation. Curette cysts and remove pericystic sclerotic walls. Depending on cyst diameter, patient age and activity...

Open the catalog to page 4

Vacuum Mixing of Bone Cement Mix cement in a closed vacuum mixing system to reduce micro and macro pores and decrease the risk of cracks in the cement.5,7,9,33 The handling properties of the bone cement are highly dependent on the temperatures of the cement and the operating room. Higher temperatures make for a shorter sticky and dough phases and a faster setting time. High viscosity bone cement like Biomet Bone Cement R and Refobacin® Bone Cement R can be pre-chilled if a longer sticky and dough phase is required. Note: Inclusions of blood and laminations in the cement mass reduces the...

Open the catalog to page 5

Implanting Final Components The components may be cemented sequentially or simultaneously. Tibia Delivery and Pressurization of Bone Cement on Bone Deliver the cement to a clean, dry bone bed following pulse lavage. Use a cement gun and an adequate nozzle in order to minimize the risk of air and blood entrapment and achieve sufficient pressurization. Apply cement on bone and pressurize the cement, striving for penetration of 3-4 mm to help ensure optimal fixation and stress distribution. Total Knee Replacement Partial Knee Replacement Insertion Components To facilitate insertion, flex the...

Open the catalog to page 6

Femur Delivery and Pressurization of Bone Cement on Bone Deliver the cement to a clean, dry bone bed following pulse lavage. Apply a layer of cement over the entire boneopposing surface of the femoral component using a cement gun and an appropriate nozzle. Total Knee Replacement Pressurize the cement, striving for penetration of 3-4 mm to help ensure optimal fixation and stress distribution. Avoid contamination of the implant-cement interface. Partial Knee Replacement Insertion Components The components are inserted and driven into position with impactors, followed by trial liner insertion...

Open the catalog to page 7

Implant - Cement Interface General Clinical Problem in Knee Arthroplasty: Tibial Loosening IMPLANT Tibial loosening between cement and implant is not limited to any particular cement brand or tibial component design. The overriding factor is the cementation technique.4* • Knee revisions in US 2017 were projected to be 94,500 with an annual growth rate of 6.2% 36 • Aseptic loosening of cemented tibial components remain a major cause of failure. It is shown in literature to account for 24% of all knee revisions 3 • Micro motion at the implant-cement or cement-bone interface can generate wear...

Open the catalog to page 8

Implant - Cement Interface Independent Study with Stryker Triathlon® Tibial Trays and Simplex® and PALACOS® Bone Cements 4* Conclusions • Under laboratory conditions, a clean tibial tray-cement interface is strong, but much stronger when the keel is cemented • Earlier application of the cement to metal increases bond strength while later application reduces bond strength • Fat contamination of the tibial tray-cement interface reduces bond strength, but application of cement to the underside of the tibial tray prior to insertion substantially mitigates this Solutions for Modern Cementing...

Open the catalog to page 9

Bone Cement Bone Cement IMPLANT Polymethyl methacrylate (PMMA) bone cements fill the space between prostheses and bone, transmitting and evenly distributing loads. The main considerations are: • Good mechanical properties • Consistent handling properties Mixing Under Vacuum Mixing under vacuum reduces both micro and macro pores.8* Deliver the cement with a cement gun and nozzle suitable for the application.10 • Improved cement strength and fatigue life 7 • Lower risk of aseptic loosening due to cracks in the cement 7-10* • Delivery of reproducible results • Less exposure to monomer fumes...

Open the catalog to page 10

Cement - Bone Interface Bone Bed Preparation IMPLANT Preparation of the bone bed with a pulsative lavage system, like the Pulsavac® Plus Wound Debridement System, helps to ensure solid cement fixation. Clean repeatedly until clear fluid is received in the return line to reduce the amount of debris, blood, bacteria and fat.29-31 • To obtain proper cement penetration and fixation into the cancellous bone 38 • Reduce the risk for revision due to aseptic loosening 3,18 • Reduce the risk for fat embolism 29 Delivery • A uniform, deep bone cement mantle provides for optimal fixation and stress...

Open the catalog to page 11

Biomet Bone Cement R and Refobacin® Bone Cement R Reliable performance Zimmer Biomet’s bone cements follow the standard specifications in all respects of material used, formulation and manufacturing methods. Bone cements from Zimmer Biomet show reliable performance based on international laboratory standard testing. 39,40 Easy handling Biomet Bone Cement R and Refobacin® Bone Cement R can be mixed both by hand and in a vacuum mixing system. However, Modern Cementing Technique recommends using a vacuum mixing system such as the ClearMix™ Vacuum Mixers for mixing and delivery of bone cement....

Open the catalog to page 12All Zimmer Biomet catalogs and technical brochures

-

ROSA ONE® Brain System

7 Pages

-

MODULAR FEMORAL Revision System

14 Pages

Archived catalogs

-

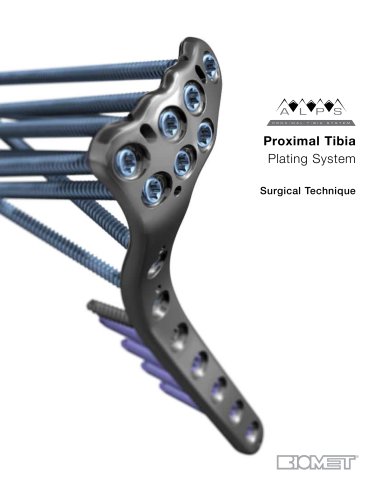

A.L.P.S.®

44 Pages

-

Constrained Posterior Stabilized

12 Pages

-

Persona PERSONALIZED KNEE

7 Pages

-

Avenir® Femoral Hip System

12 Pages

-

The CLS® Spotorno® Stem

16 Pages

-

Alloclassic®Zweymüller®Stem

12 Pages

-

®Zimmer® Segmental System

6 Pages

-

NexGen® RH Knee

8 Pages

-

Persona-Partial

12 Pages

-

Zimmer Natural Nail System

8 Pages

-

tourniquet-systems-brochure

8 Pages

-

CoAxial Spray Kit

8 Pages

-

Biologics

24 Pages

-

PowerPump DP System

2 Pages

-

Sidus

40 Pages

-

Ankle Fix System 4.0

8 Pages

-

Anatomical Shoulder System

6 Pages

-

Fitmore Hip Stems

6 Pages

-

NexGen High-Flex Implant

8 Pages

-

Trabecular Metal ™Glenoid

4 Pages

-

Anatomical Shoulder ™ System

6 Pages

-

Zimmer ® PSI Shoulder

6 Pages

-

Zimmer personna

12 Pages

-

ZImmer iASSIST

44 Pages

-

Fitmore ® Hip Stem

24 Pages

-

Persona Knee

6 Pages

-

Trauma Solutions

10 Pages

-

Colagen Repair Patch

2 Pages

-

Fitmore® Hip Stem

6 Pages

-

Zimmer® Segmental System

6 Pages