Website:

INOXPA

Website:

INOXPA

Excertos do catálogo

Leakage Butterfly Valve A P P L I C AT I O N The A470 leakage butterfly valve can be used in most liquid product applications in the food-processing, pharmaceutical and chemical industries. The valve A470 offers a safe separation of products and prevents accidental mixing in case of gasket failure. The most usual applications are the ones that require safe separation of the product and CIP solutions in a single point or at the end of a manifold (e.g. CIP return) or entry of a CIP solution into a tank (through a spray ball). O P E R AT I N G P R I N C I P L E The A470 valve provides double safety: the two discs are simultaneously actuated by only one actuator. Open valve Product Closed valve CIP Solution Chamber cleaning FT 10.011.33.01EN·(0) 2023/02 pàg. 1/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. When the two discs are closed, there is a chamber between them. The chamber is under atmospheric pressure as it opens to the exterior, thus, in case of failure of any of the two gaskets, leakage of the liquid product will indicate any possible mixing of products. The state of the gaskets is supervised by means of either of the leakage detectors. The other superior detector controls the entry of the cleaning solution to prevent any kind of contamination in the chamber. These two leakage detectors provide optimal protection and enable cleaning of the intermediate chamber.

Abrir o catálogo na página 1

Compact and robust design. Low pressure losses. TECHNICAL SPECIFICATIONS pag. 2/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. Materials Disc Body halves Other St. St. parts Gasket Available sizes DIN EN 10357 series A DN 25 - DN 100 Connections Weld Operating limits Working temperature -10oC to 120oC Minimum working pressure (absolute) 20 kPa (0,2 bar) Maximum working pressure 1000 kPa (10 bar) 1) For rotating the valve disc...

Abrir o catálogo na página 2

pag. 3/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. Compressed air consumption at Pre| = 6 bar (litres N/cycle) 1) Actuator with specific stroke to A470 valves Standard assembly 1) Actuator with specific stroke to A470 valves

Abrir o catálogo na página 3

pag. 4/4 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com.

Abrir o catálogo na página 4Todos os catálogos e folhetos técnicos INOXPA

-

C-TOP S

4 Páginas

-

Manifold

3 Páginas

-

INNOVA N

3 Páginas

-

INNOVA K

4 Páginas

-

STERIPIG

2 Páginas

-

CIP

3 Páginas

-

M-226

4 Páginas

-

MM

3 Páginas

-

8100X

2 Páginas

-

ME-6100

3 Páginas

-

ME-4100

2 Páginas

-

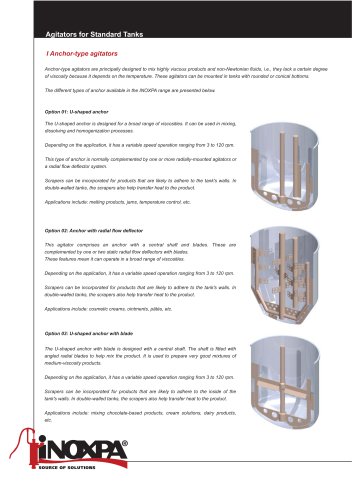

Agitators for Standard Tanks

6 Páginas

-

NBI

2 Páginas

-

81700 / 82700 / 83700

4 Páginas

-

7550

2 Páginas

-

72700

2 Páginas

-

A480 / A490

5 Páginas

-

74700

3 Páginas

-

INNOVA Mini K

4 Páginas

-

INNOVA Mini N

3 Páginas

-

MV

5 Páginas

-

MBC

4 Páginas

-

CMC-ATEX

3 Páginas

-

Fermentation systems

2 Páginas

-

MCR

14 Páginas

-

CXC

2 Páginas

-

NHS

2 Páginas

-

DINAMIX SMX

5 Páginas

-

BMA

2 Páginas

-

MCR

4 Páginas

-

Kiber KS

4 Páginas

-

DCS

3 Páginas

-

DCH+

3 Páginas

-

DCH

3 Páginas

-

TLS

3 Páginas

-

SLRT

2 Páginas

-

HLR

2 Páginas

-

SLR

4 Páginas

-

ASPIR

5 Páginas

-

RVN

3 Páginas

-

RV

2 Páginas

-

Estampinox EFI

4 Páginas

-

Hyginox SEN

3 Páginas

-

HYGINOX SE

5 Páginas

-

Prolac HCP SP

4 Páginas

-

PROLAC HCP WFI

2 Páginas

-

PROLAC HCP

5 Páginas

-

DIN-FOOD

2 Páginas

-

Angular filter

17 Páginas

-

BUTTERFLY AND BALL VALVES

4 Páginas

-

INNOVA SEAT VALVES

36 Páginas

-

FOOD INDUSTRY

10 Páginas

-

PHARMACY AND COSMETICS

10 Páginas