Website:

INOXPA

Website:

INOXPA

Excertos do catálogo

FT 20.073.33.01EN · (B) 2024/10 pàg. 1/5 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. DINAMIX SMX Side Entry Agitator O P E R AT I N G P R I N C I P L E Side entry agitators DINAMIX SMX are used for the homogenization of liquids stored in large volume tanks. They are powered by means of a geared motor and are installed inclined in the lower part of the shell of the tank. The rotation of the propeller creates a flow that pushes the product towards the bottom of the tank, making it rise to the surface of the liquid through the tank wall on the opposite side of the agitator. This effect is favoured if the closure has a dished head. Likewise, the agitator is installed off-centre with respect to the tank to favour a circular flow in the radial plane. In this way, a complete homogenization of the product is ensured. A P P L I C AT I O N S Lateral agitators are an economical and effective solution for storage tanks in the food, pharmaceutical and cosmetic industries. The most important application is the maintenance and homogenization in large volume tanks of low viscosity products such as wine, oil, milk, beer, alcohol, etc. D E S I G N A N D F E AT U R E S Robust and hygienic construction. Standardised EN 1092 PN 10 flange. Stainless steel lantern to facilitate the inspection and maintenance of the mechanical seal. Hygienic design to avoid dead and difficult access spots to easy cleaning. High-efficiency impeller fixed to the shaft through a threaded hygienic connection. Different types of IE3 gear motors with food grade oil. Electric motor, 3 ph, IP55, 1500 rpm. CONFIGURABLE ELEMENTS The agitator has a modular design and is fully configurable with different options of motors, sealing system, surface finish, elastomeric materials and, in addition, the possibility of ATEX certification.

Abrir o catálogo na página 1

pàg. 2/5 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. Surface finish Standard surface finish is Ra ≤ 0,8 μm. Also available with Ra ≤ 0,4μm surface finish for pharmaceutical applications. Sealing system As standard with a single mechanical seal. Optional hygienic system. Available with different sealing systems on request. Different drives As standard, available with highefficiency IE3 worm gear drives or IE3 parallel shaft...

Abrir o catálogo na página 2

OPTIONS Agitator without the lantern. SiC/SiC mechanical seal. Gaskets: FPM. Motor with shroud. Hygienic design. ATEX certification. TECHNICAL SPECIFICATIONS pag. 3/5 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. Parts in contact with the product Other steel parts Mechanical seal Mechanical seal gasket Surface finish Operating limits Working pressure Working temperature Agitators with worm gear drive Flow Tank Speed Power...

Abrir o catálogo na página 3

DIMENSIONS Agitators with worm gear drive pag. 4/5 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. Flange Shaft Standard W/O Lantern

Abrir o catálogo na página 4

Agitators with parallel shaft drive pag. 5/5 The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our website www.inoxpa.com. Flange Shaft Standard W/O Lantern Shut-off Standard W/O Lantern Shut-off

Abrir o catálogo na página 5Todos os catálogos e folhetos técnicos INOXPA

-

C-TOP S

4 Páginas

-

Manifold

3 Páginas

-

INNOVA N

3 Páginas

-

INNOVA K

4 Páginas

-

STERIPIG

2 Páginas

-

CIP

3 Páginas

-

M-226

4 Páginas

-

MM

3 Páginas

-

8100X

2 Páginas

-

ME-6100

3 Páginas

-

ME-4100

2 Páginas

-

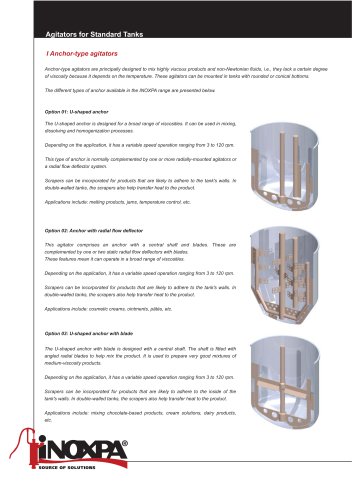

Agitators for Standard Tanks

6 Páginas

-

NBI

2 Páginas

-

81700 / 82700 / 83700

4 Páginas

-

7550

2 Páginas

-

72700

2 Páginas

-

A470

4 Páginas

-

A480 / A490

5 Páginas

-

74700

3 Páginas

-

INNOVA Mini K

4 Páginas

-

INNOVA Mini N

3 Páginas

-

MV

5 Páginas

-

MBC

4 Páginas

-

CMC-ATEX

3 Páginas

-

Fermentation systems

2 Páginas

-

MCR

14 Páginas

-

CXC

2 Páginas

-

NHS

2 Páginas

-

BMA

2 Páginas

-

MCR

4 Páginas

-

Kiber KS

4 Páginas

-

DCS

3 Páginas

-

DCH+

3 Páginas

-

DCH

3 Páginas

-

TLS

3 Páginas

-

SLRT

2 Páginas

-

HLR

2 Páginas

-

SLR

4 Páginas

-

ASPIR

5 Páginas

-

RVN

3 Páginas

-

RV

2 Páginas

-

Estampinox EFI

4 Páginas

-

Hyginox SEN

3 Páginas

-

HYGINOX SE

5 Páginas

-

Prolac HCP SP

4 Páginas

-

PROLAC HCP WFI

2 Páginas

-

PROLAC HCP

5 Páginas

-

DIN-FOOD

2 Páginas

-

Angular filter

17 Páginas

-

BUTTERFLY AND BALL VALVES

4 Páginas

-

INNOVA SEAT VALVES

36 Páginas

-

FOOD INDUSTRY

10 Páginas

-

PHARMACY AND COSMETICS

10 Páginas