Website:

INOXPA

Website:

INOXPA

Excertos do catálogo

SEAT VALVES

Abrir o catálogo na página 1

NAVIGATION INSTRUCTIONS Go to page Previous Summary Next

Abrir o catálogo na página 2

SUMMARY INOXPA: EXCELLENCE IN HYGIENIC DESIGN ARGUMENTS & BENEFITS SINGLE SEAT CONCEPT TABLE: INNOVA SINGLE SEAT MIXPROOF CONCEPT TABLE: MIXPROOF VALVE IDENTIFICATION AND ORDER CODES

Abrir o catálogo na página 3

INOXPA: EXCELLENCE IN HYGIENIC DESIGN Food safety must be ensured by a design made in accordance with hygienic principles in order to prevent contamination. INOXPA have three priority objectives in the hygienic design of our components: • To prevent the risk of physical, chemical or microbiological contamination • To facilitate the cleaning and disinfection of the installation • To contribute towards the preservation and maintenance of the equipment The main factors we consider are: • The materials of the components • The typology and finish of the contact surfaces • Accessibility to the...

Abrir o catálogo na página 4

The surfaces are made of non-absorbent materials that are resistant to detergents, disinfectants and other cleaning products in order to prevent any detachment. The surfaces are polished until low roughness is attained (equal to or less than Ra 0.8µm), the welds are left flush and blemish-free, thus steps between the different surfaces are avoided. The material used is AISI-316L stainless steel in the parts that come into contact with the product, due to its high level of resistance to corrosion, pH and the high temperatures of the cleaning products. THE CONCEPT OF “CLEANABILITY” INOXPA...

Abrir o catálogo na página 5

ARGUMENTS & BENEFITS SEAT VALVES FOR HYGIENIC USE INNOVA seat valves are designed to offer solutions in hygienic applications for industries in the most demanding sectors such as food, beverage, health care or pharmaceutical. The extensive experience of INOXPA, with more than 40 years introducing hundred thousand of valves in the market, is reflected in this wide and complete range of seat valves, which thanks to its advanced design, versatile and reliable, meets the highest hygienic standards. The different INNOVA models share many of their components: bodies, shafts and gaskets, which...

Abrir o catálogo na página 6

MORE BENEFITS The advanced design of the seals, the plug and the seat guarantee a perfect sealing and thanks to the metal-metal contact between the plug and the body, the life cycles of the valve are extended, which implies savings in maintenance. INNOVA valves reduce the number of their components and share them, which means a reduction in installation, maintenance and inventory costs. Its design and reliability extend the life of the valve, make it more hygienic, reducing the consumption of water and cleaning products, causing a minimum amount of product waste. Less investment - more...

Abrir o catálogo na página 7

SINGLE SEAT CONCEPT INOXPA has a wide range of seat valves available, which mainly feature high productivity and lower operating and maintenance costs. They offer a consistent product quality and impeccable cleaning. Parts in contact with the product AISI 316L (1.4404) Other stainless steel parts AISI 304 (1.4301) Gasket EPDM - HNBR* - FPM* Surface finish: Internal Bright polish Ra ≤ 0,8 μm - 0,5*μm External Matt AVA I L A B L E S I Z E S : DIN EN 10357 series A (previously DIN 11850 series 2) ASTM A269/270 (corresponds to OD pipe) CONNECTIONS: Weld, Clamp*, Male* Temperature range (EPDM)...

Abrir o catálogo na página 8

INNOVA SINGLE SEAT VALVES INNOVA TANK BOTTOM VALVES

Abrir o catálogo na página 9

N SHUT-OFF SINGLE SEAT VALVE Flow inlet via the lower body The valve is designed for the direction of product flow from the LOWER to the UPPER body. In order to prevent water hammering the closing acts from the UP position to the DOWN position against the flow direction. OPTIONS > Double acting pneumatic actuator. > External position sensors. > Heating jacketed body. > Steam barrier. > Manual drive. > Twin stop.

Abrir o catálogo na página 10

M SHUT-OFF SINGLE SEAT VALVE Flow inlet via the upper body The INNOVA M-type valve is a pneumatic shut-off seat valve for hygienic applications. The valve is designed for the direction of product flow from the UPPER to the LOWER body. In order to prevent water hammering the closing acts from the DOWN position to the UP position against the flow direction. H O U S I N G C O M B I N AT I O N S > Double acting pneumatic actuator. > External position sensors. > Heating jacketed body. > Steam barrier. > Manual drive. > Twin stop.

Abrir o catálogo na página 11

DIVERT SINGLE SEAT VALVE The INNOVA K-type valve is a pneumatic divert seat valve designed for hygienic applications. This valve is designed to manage converging flows, given that it closes against the direction of flow, the inlet is via the upper or lower bodies and outlet via the central body. > Double acting pneumatic actuator. > External position sensors. > Heating jacketed body. > Steam barrier. > Manual drive. > Twin stop.

Abrir o catálogo na página 12

DIVERT SINGLE SEAT VALVE The L type valve is a pneumatic divert seat valve designed for hygienic applications. This valve is designed to manage diverging flows, given that it closes against the direction of flow, the inlet is via the central body and outlet via the upper or lower bodies. > Double acting pneumatic actuator. > External position sensors. > Heating jacketed body. > Steam barrier. > Manual drive. > Twin stop.

Abrir o catálogo na página 13

G CONTROL SINGLE SEAT VALVE Progressive opening or adjustment The INNOVA G-type valve is a pneumatic flow control single seat valve for hygienic applications. Its main function involves regulating flow, controlling pressure and level. The plug’s design enables equal percentage flow control to obtain the required Kv factor. This type of control is recommended for systems with significant flow or differential pressure variations. Positioning is controllable either manually or using a process parameter vi the positioning sensor. OPTIONS > Double acting pneumatic actuator. > Heating jacketed...

Abrir o catálogo na página 14

J OVERFLOW SINGLE SEAT VALVE The INNOVA J-type valve is a pneumatic single seat valve designed for use as overflow valve in hygienic installations. Its most important applications involve operating as a by-pass valve for positive displacement pumps or protecting equipment against excessive pressure. Adjusting the screw on the upper part sets the spring pressure, which sets the valve’s closing pressure. The valve comes with an actuator that enables liquid to flow during CIP cleaning processes. H O U S I N G C O M B I N AT I O N S > External position sensors. > Heating jacketed body. > Steam...

Abrir o catálogo na página 15Todos os catálogos e folhetos técnicos INOXPA

-

C-TOP S

4 Páginas

-

Manifold

3 Páginas

-

INNOVA N

3 Páginas

-

INNOVA K

4 Páginas

-

STERIPIG

2 Páginas

-

CIP

3 Páginas

-

M-226

4 Páginas

-

MM

3 Páginas

-

8100X

2 Páginas

-

ME-6100

3 Páginas

-

ME-4100

2 Páginas

-

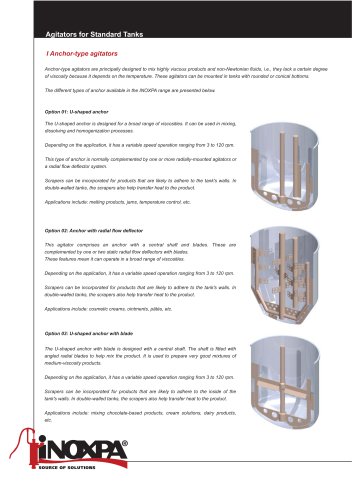

Agitators for Standard Tanks

6 Páginas

-

NBI

2 Páginas

-

81700 / 82700 / 83700

4 Páginas

-

7550

2 Páginas

-

72700

2 Páginas

-

A470

4 Páginas

-

A480 / A490

5 Páginas

-

74700

3 Páginas

-

INNOVA Mini K

4 Páginas

-

INNOVA Mini N

3 Páginas

-

MV

5 Páginas

-

MBC

4 Páginas

-

CMC-ATEX

3 Páginas

-

Fermentation systems

2 Páginas

-

MCR

14 Páginas

-

CXC

2 Páginas

-

NHS

2 Páginas

-

DINAMIX SMX

5 Páginas

-

BMA

2 Páginas

-

MCR

4 Páginas

-

Kiber KS

4 Páginas

-

DCS

3 Páginas

-

DCH+

3 Páginas

-

DCH

3 Páginas

-

TLS

3 Páginas

-

SLRT

2 Páginas

-

HLR

2 Páginas

-

SLR

4 Páginas

-

ASPIR

5 Páginas

-

RVN

3 Páginas

-

RV

2 Páginas

-

Estampinox EFI

4 Páginas

-

Hyginox SEN

3 Páginas

-

HYGINOX SE

5 Páginas

-

Prolac HCP SP

4 Páginas

-

PROLAC HCP WFI

2 Páginas

-

PROLAC HCP

5 Páginas

-

DIN-FOOD

2 Páginas

-

Angular filter

17 Páginas

-

BUTTERFLY AND BALL VALVES

4 Páginas

-

FOOD INDUSTRY

10 Páginas

-

PHARMACY AND COSMETICS

10 Páginas