Website:

INOXPA

Website:

INOXPA

Excertos do catálogo

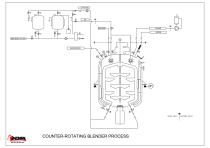

Counter-Rotating Blenders I Application Counter-rotating blenders are used for mixing and homogenizing dispersed products at a controlled temperature with an optimum performance, regardless of the product viscosity. These units are intended primarily for pharmaceutical, cosmetics, food and personal care products industries. They are ideal for processes which require heating, vacuum, premixing, additions, vigorous agitation, emulsion or dispersion, as well as pressure and temperature. The skid can work at -1 to 0.5 bar and the double jacket - up to 3 bar. The operating temperature is between -7 a 120 ºC. It is possible to control the following parameters: temperature, pressure, pH, weight and viscosity. The unit is provided with a cleaning system with rotating spray balls in order to be connected to a CIP and SIP cleaning system. Some examples of products that can be treated with these units are all kinds of creams, gels, sunscreens, depilatories, makeup, deodorants, sauces, pates, pastes, shoe creams, emulsions, paraffin mixtures, wax mixtures, carbopol dispersions, tooth pastes, products intended for drugstores and parapharmacies. I Principle of operation The unit has a sealed tank where mixing takes place by means of an anchor type agitator, a central shaft with counter-rotating blades that move in the opposite direction to the anchor, and an emulsifying disperser located at the bottom of the shaft. The unit normally operates under vacuum during the entire duration of the mixing process. When the agitation starts, the anchor and the central blades rotate slowly while the bottom mixer is put into operation. Subsequently, the product to be dispersed or emulsified is added and the speed of the blades on the central shaft is increased. When the mixing is complete, the agitator speed decreases and the bottom mixer is stopped; at the same time the chamber begins to cool down. When the product reaches the desired temperature, any required additives are added to the mixture, typically when cold; depending on the process, the speed of the agitators may be increased slightly. It is possible to recirculate the product and, if necessary, an emulsifier can be added to the process. The product discharge system can be by gravity or with a pump and, if necessary, using positive pressure. Finally, the tank is cleaned by the CIP system.

Abrir o catálogo na página 1

Counter-Rotating Blenders I Materials Parts in contact with the product Other stainless steel parts Interior surface finish Exterior surface finish AISI 316 (EN 14404) AISI 304 (EN 14301) bright polish, Ra ≤ 0.8 μm bright polish, Ra ≤ 0.8 μm I Design and features These units are available in 3 arrangements: on support base, on support feet and a metal structure, or on concrete floor, with or without automatic lid lifting. The units with support bases are designed to accept all auxiliary equipment necessary for the unit to operate autonomously. These units are built to FDA standards. For...

Abrir o catálogo na página 2

Counter-Rotating Blenders Agitation system The counter-rotating agitation system consists of two main agitation elements: an anchor with two arms with welded inclined blades -all removable-, rotating in one direction and pushing the material upwards, and a central shaft with inclined blades, which rotates in the opposite direction to the anchor, pushing the product downwards. All the blades have holes to facilitate the flow of the product. The structure of the anchor is made from hollow tube for easy cleaning and to reduce weight. The two arms are fitted with scrapers that act against the...

Abrir o catálogo na página 3

Command and control system The unit is provided with a control and power panel independently of the control area which includes a touch screen and has a restricted programming and access system. The pneumatic control system is installed in a separate panel with banks of solenoid valves. This system activates the production programmes which, in turn, control the process valves and ancillary services. All the elements are mounted in IP-65 protection against dust and water. The equipment can be provided with a weighing system with load cells and a weight terminal with the possibility of...

Abrir o catálogo na página 4

I General dimensionsUnit with one support base The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Abrir o catálogo na página 5

I General dimensionsUnit with two support bases The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Abrir o catálogo na página 6

I General dimensions Unit with lid lifting system The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Abrir o catálogo na página 7

I General dimensions Unit with lid lifting system /jilSKHRV L SOURCE OF SOLUTIONS The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Abrir o catálogo na página 8

I General dimensions Unit without lid lifting system The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Abrir o catálogo na página 9

I General dimensions Unit without lid lifting system The information is for guidance only. We reserve the right to modify any material or feature without notice in advance. Photos are not binding. For further information, please, consult our web site. www.inoxpa.com

Abrir o catálogo na página 10

BANYOLES (Grona) Spain COUNTER-ROTATING BLENDER PROCESS

Abrir o catálogo na página 11

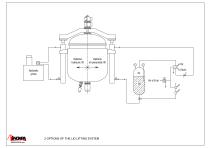

BANYOLES (Grona) Spain AUXILIARY SERVICES FOR THE COUNTER-ROTATING BLENDER TANK WITH HEATING JACKET

Abrir o catálogo na página 12

BANYOLES (Girona) Spain 2 OPTIONS OF THE LID LIFTING SYSTEM

Abrir o catálogo na página 14Todos os catálogos e folhetos técnicos INOXPA

-

C-TOP S

4 Páginas

-

Manifold

3 Páginas

-

INNOVA N

3 Páginas

-

INNOVA K

4 Páginas

-

STERIPIG

2 Páginas

-

CIP

3 Páginas

-

M-226

4 Páginas

-

MM

3 Páginas

-

8100X

2 Páginas

-

ME-6100

3 Páginas

-

ME-4100

2 Páginas

-

Agitators for Standard Tanks

6 Páginas

-

NBI

2 Páginas

-

81700 / 82700 / 83700

4 Páginas

-

7550

2 Páginas

-

72700

2 Páginas

-

A470

4 Páginas

-

A480 / A490

5 Páginas

-

74700

3 Páginas

-

INNOVA Mini K

4 Páginas

-

INNOVA Mini N

3 Páginas

-

MV

5 Páginas

-

MBC

4 Páginas

-

CMC-ATEX

3 Páginas

-

Fermentation systems

2 Páginas

-

CXC

2 Páginas

-

NHS

2 Páginas

-

DINAMIX SMX

5 Páginas

-

BMA

2 Páginas

-

MCR

4 Páginas

-

Kiber KS

4 Páginas

-

DCS

3 Páginas

-

DCH+

3 Páginas

-

DCH

3 Páginas

-

TLS

3 Páginas

-

SLRT

2 Páginas

-

HLR

2 Páginas

-

SLR

4 Páginas

-

ASPIR

5 Páginas

-

RVN

3 Páginas

-

RV

2 Páginas

-

Estampinox EFI

4 Páginas

-

Hyginox SEN

3 Páginas

-

HYGINOX SE

5 Páginas

-

Prolac HCP SP

4 Páginas

-

PROLAC HCP WFI

2 Páginas

-

PROLAC HCP

5 Páginas

-

DIN-FOOD

2 Páginas

-

Angular filter

17 Páginas

-

BUTTERFLY AND BALL VALVES

4 Páginas

-

INNOVA SEAT VALVES

36 Páginas

-

FOOD INDUSTRY

10 Páginas

-

PHARMACY AND COSMETICS

10 Páginas