Excertos do catálogo

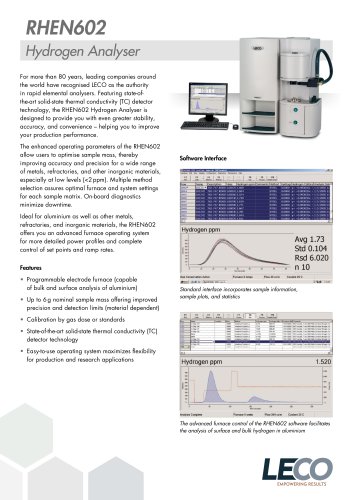

RHEN602 Hydrogen Analyser For more than 80 years, leading companies around the world have recognised LECO as the authority in rapid elemental analysers. Featuring state-ofthe-art solid-state thermal conductivity (TC) detector technology, the RHEN602 Hydrogen Analyser is designed to provide you with even greater stability, accuracy, and convenience – helping you to improve your production performance. The enhanced operating parameters of the RHEN602 allow users to optimise sample mass, thereby improving accuracy and precision for a wide range of metals, refractories, and other inorganic materials, especially at low levels (<2 ppm). Multiple method selection assures optimal furnace and system settings for each sample matrix. On-board diagnostics minimize downtime. Software Interface Ideal for aluminium as well as other metals, refractories, and inorganic materials, the RHEN602 offers you an advanced furnace operating system for more detailed power profiles and complete control of set points and ramp rates. Features • Programmable electrode furnace (capable of bulk and surface analysis of aluminium) • Up to 6 g nominal sample mass offering improved precision and detection limits (material dependent) Standard interface incorporates sample information, sample plots, and statistics • Calibration by gas dose or standards • State-of-the-art solid-state thermal conductivity (TC) detector technology • Easy-to-use operating system maximizes flexibility for production and research applications The advanced furnace control of the RHEN602 software facilitates the analysis of surface and bulk hydrogen

Abrir o catálogo na página 1

Specifications Instrument Range at 1 g* Standards, multi-point; manual; gas dose Analysis Time 7 min (includes outgas/purge/analysis delay) Sample Size Detection Method Thermal Conductivity Chemical Reagents Anhydrous Magnesium Perchlorate (MgCIO4 ) Sodium Hydroxide on an inert base Schutze Reagent Copper Sticks and Turnings Gases Required Carrier: Compressed Air, 40 psi (2.8 bar) ±10 %; source must be oil and water free Gas Flow Rates Carrier: Furnace Type: Electrode furnace; current, power, and temperature control Single Furnace/ Determinator Dimensions†† Sound Pressure Level 31 in H x...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos LECO

-

eBook - Energy & Fuels Applications

40 Páginas

-

Supplies for Organic Analysis – Catalog

28 Páginas

-

Supplies for Metallograhpy – Catalog

48 Páginas

-

Sectioning Machine Accessories

2 Páginas

-

Cornerstone Mobile

2 Páginas

-

928 Series

6 Páginas

-

CS844 Series

6 Páginas

-

832 Series

6 Páginas

-

Solutions for Metals Analysis

4 Páginas

-

PX400/PX500 Grinder/Polisher Series

4 Páginas

-

GDS900

8 Páginas

-

Pegasus BT 4D

6 Páginas

-

Metabolomics Solutions from LECO

8 Páginas

-

PR36 Mounting Press

2 Páginas

-

Organic Supplies – Catalog

28 Páginas

-

CHN828 with S832 Add-On

2 Páginas

-

CS744/844 with S832 Add-On

2 Páginas

-

MX500

2 Páginas

-

MX400

2 Páginas

-

PAX-it 2

2 Páginas

-

SX100M

2 Páginas

-

Macro Digital Microscope

2 Páginas

-

LCB3100

2 Páginas

-

L-PAL3

2 Páginas

-

Sectioning Machines (EU)

18 Páginas

-

MSX205 M-Series

2 Páginas

-

MSX255 M-Series

2 Páginas

-

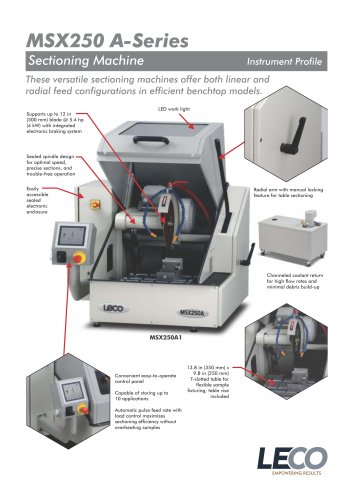

MSX250 A-Series

2 Páginas

-

MSX432 A-Series

2 Páginas

-

MSX305 A-Series

2 Páginas

-

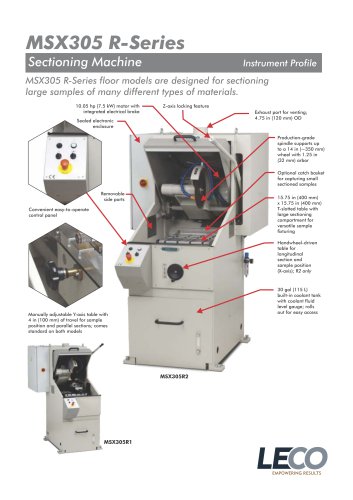

MSX305 R-Series

2 Páginas

-

Solution for Cement Analysis

4 Páginas

-

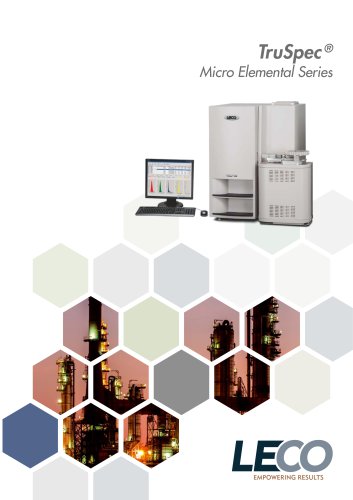

TruSpec Micro

4 Páginas

-

PX300 Grinder/Polisher

2 Páginas

-

DH603

4 Páginas

-

AF700

2 Páginas

-

AC500

2 Páginas

-

VX4

1 Páginas

-

AMH55

6 Páginas

-

EATC Berlin

8 Páginas

-

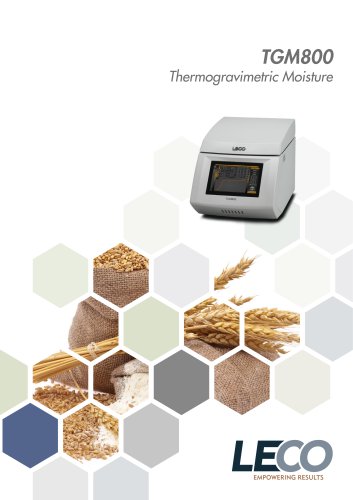

TGM800

6 Páginas

-

736 Series

6 Páginas

-

836 Series

6 Páginas

-

eBook Food

48 Páginas

-

RC612

4 Páginas

-

CS744

6 Páginas

-

AC600

4 Páginas

-

TGA801

6 Páginas

-

828 Series

6 Páginas

-

Pegasus BT

6 Páginas

-

Pegasus GC-HRT+ 4D

8 Páginas

-

Pegasus GC-HRT+

8 Páginas

-

Solutions for Food Analysis

4 Páginas