Excertos do catálogo

Bubble leak testing of tank bottom plate welds and shell to bottom plate welds The BHFTECH vacuum box has been designed for the operators according to API 650/653 recommendations. Bubble leak or vacuum box testing is an integral part of tank inspections as required by the American Petroleum Institute (API) and other international standards associations to establish the condition of tank bottom plate welds and shell-tobottom plate welds Flat Bottom Vacuum Box Features Designed to API 650/653 recommendations 750 mm (29.53 in) weld inspection length, improves inspection times and reduces operator fatigue Integrated LED lights provide the required light Flat Bottom Full Transparent intensity as specified by API and ASME inspection standards Screen glare and shadows from external light sources are eliminated Calibrated vacuum relief valve ensures the correct vacuum is generated, too high a vacuum can damage Inside Corner Vacuum Box the vacuum box and cause injury to the operator Bubble Leak Testing Superior build quality with robust cast aluminum body Two-stage seal design to improve initial vacuum, especially on large lap welds Electric vacuum pump or compressor driven Model No Flat Bottom box for testing butt welds on flat surfaces Inside Corner Vacuum Box Bubble Leak Testing Corner vacuum boxes are specifically designed for testing the inside corner, where the bottom meets the sidewall at 90 degrees Complete Transparent Flat Bottom box for testing butt welds on flat surfaces 110 General Patters Road. Chennai – 600002. India. +919677296252, bhftech.info@gmail.co

Abrir o catálogo na página 1

More Efficient: Vacuum Box LEDs The optional built-in LEDs provide the recommended light intensity along the weld under test by API 650. The internal LEDs eliminate the view window reflection that occurs when external lights are used to brighten the weld inspection area. You can easily turn the LEDs on and off, eliminating the need for you to move standard halogen floodlights as you move around the tank Better Accuracy: Calibrated Gauge The V750 Vacuum Box comes with an industrial 50.8 mm (2 in) face pressure gauge rated to 762 mm (30 in) of mercury as required by ASME V Article 10–Bubble...

Abrir o catálogo na página 2Todos os catálogos e folhetos técnicos Meditech Technologies India

-

Vacuum Glove Box Metal Body

4 Páginas

-

stainless steel Vacuum Chamber Cube

1 Páginas

-

S S vacuum Chamber for degassing

1 Páginas

-

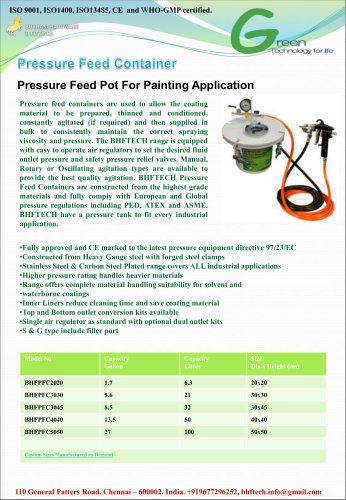

Pressure Pot For Resin casting

1 Páginas

-

Potting of Elecronic Components

3 Páginas

-

Heated Vacuum Oven

1 Páginas

-

EXPOXY RESIN BURHANI

2 Páginas

-

CLEAR CASTING RESIN-POLYSTER

1 Páginas

-

Acrylic vacuum glove box

2 Páginas

-

Acrylic Vacuum Chamber Cylinder

1 Páginas

-

Acrylic Vacuum Chamber Cube

1 Páginas

-

acrlic vacuum glove box

2 Páginas

-

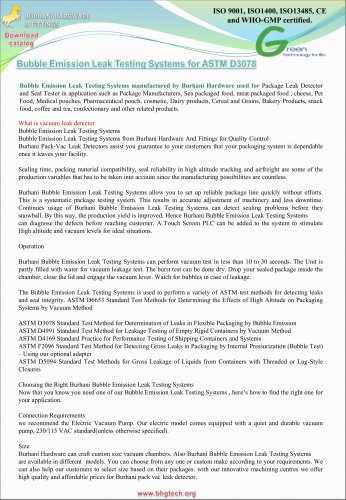

vacuum leak detector chamber cube

1 Páginas

-

vacuum degassing chamber ss tank

1 Páginas

-

Vacuum Degasser Transparent Cylinder

1 Páginas

-

Vacuum Degasser Transparent Cube

1 Páginas

-

SS Vacuum Chamber for drying

1 Páginas

-

SS Vacuum Degassing Chamber

1 Páginas

-

resin degassing vacuum chamber

2 Páginas

-

pack vac leak detector

2 Páginas

-

clear acrylic round vacuum chamber

1 Páginas

-

clear acrylic cube vacuum chamber

1 Páginas

-

xenon test chamber

3 Páginas

-

walk in stability chamber

12 Páginas

-

walk in cooler

11 Páginas

-

thermo hygrostat chamber

10 Páginas

-

plant growth room

2 Páginas

-

photostability chamber

9 Páginas

-

humidity temp stability chamber

7 Páginas

-

Humidity Chamber

10 Páginas

-

Freezer thaw chamber

9 Páginas

-

cold room

10 Páginas

-

cold room for blood bank

18 Páginas

-

co2 incubator

15 Páginas

-

BOD Incubator

10 Páginas

-

Bacteriological Incubator

4 Páginas

-

meditech dc compressor

3 Páginas

-

Solar DC Compressor

3 Páginas

-

Digital Physiograph Meditech

2 Páginas

-

stability chamber

7 Páginas

-

Blood Bank Tube sealer

1 Páginas

-

Blood Bank refrigerator tp series

12 Páginas

-

solar ice lined refrigerator

4 Páginas

-

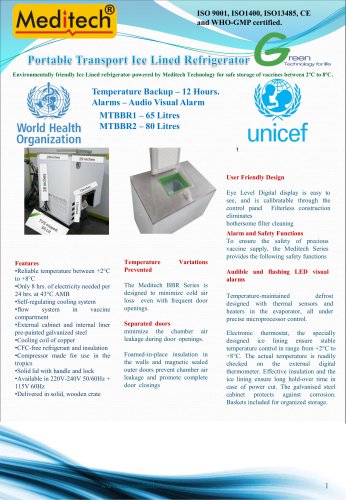

ice lined refrigerator meditech

5 Páginas

-

Solar DC Refrigerator Freezer

4 Páginas

-

platelet incubator agitator

3 Páginas

-

Blood Donor Coach Chair

1 Páginas

-

Blood Collection Monitor Meditech

5 Páginas

-

Biomedical lab Refrigerator

4 Páginas

-

Laboratory Refrigerator Touch Screen

8 Páginas

-

Incubator

2 Páginas

-

Pharmacy Refrigerator Meditech

4 Páginas

-

Meditech Blood Bank Equipments

41 Páginas

-

Incubator Meditech

2 Páginas

-

Phlebotomy Chair Meditech

1 Páginas

-

Blood Donor Chair Meditech

1 Páginas

-

Bio Medical Training Kit Meditech

2 Páginas

-

Digital Physiograph Meditech Online

2 Páginas

-

Mobile Blood Donor Couches

1 Páginas

-

Vertical Ice Lined Refrigerator

6 Páginas

-

Horizontal Ice Lined Refrigerator

4 Páginas

-

Blood Tube Sealer

1 Páginas

-

MTCR 60

6 Páginas

-

MTPS432

5 Páginas

-

MTPS360

5 Páginas

-

MTPS288

5 Páginas

-

MTPS216

5 Páginas

-

MTPS144

5 Páginas

-

MTPS72

5 Páginas

-

MBDW80

11 Páginas

-

MBDW120

11 Páginas

-

MBDW40

11 Páginas

-

Portable Refrigerator

2 Páginas

-

Laminar Air Flow Horizontal

1 Páginas

-

Blood Bank Refrigerated centrifuge

4 Páginas

-

Blood Storage Refrigerator

18 Páginas

-

Camping Cot

1 Páginas

-

MTR30

3 Páginas

-

MTR26

3 Páginas

-

ME7-2

3 Páginas

-

ME8

8 Páginas

-

MTBDR16

3 Páginas

-

MTAC60

7 Páginas

-

MTAC40

7 Páginas

-

MTAC26

3 Páginas

-

MA1000

3 Páginas

-

Respiration Pump

1 Páginas

-

Spirometer

1 Páginas

-

Smoking Burner & Stand

1 Páginas

-

Varnishing Outfit

1 Páginas

-

Elisa Plate Analyser

2 Páginas

-

Solar Blood Bank Refrigerator

6 Páginas

-

mushroom grow chamber

9 Páginas

-

Walk in type cooling cabinet

12 Páginas

-

Walk in stability chambers

12 Páginas

-

Walk in freezer

11 Páginas

-

Walk in cooler for Blood Bank

18 Páginas

-

Thermo Hygrostat Incubator

10 Páginas

-

Temperature Rooms - Hot Cold

9 Páginas

-

Temperature Chamber

7 Páginas

-

Humidity Temperature Stability Room

7 Páginas

-

Direct heat CO2 incubator

15 Páginas

-

Cold rooms

10 Páginas

-

Cold rooms for Blood Bank

18 Páginas

-

CO2 incubator

7 Páginas

-

Ultra Low Plasma freezer with backup

6 Páginas

-

Ultra Low Plasma freezer horizontal

4 Páginas

-

Ultra Low Deep freezer -40°C with Touch

11 Páginas

-

Ultra Low Deep freezer with touch

11 Páginas

-

Solar Powered Deep freezer -40°C

4 Páginas

-

Reagent Refrigerator

4 Páginas

-

Platelet agitator

7 Páginas

-

Plasmatherm plasma thawing bath

2 Páginas

-

Phlebotomy chair

1 Páginas

-

Pharmacy refrigerator

4 Páginas

-

Lab refrigerator

4 Páginas

-

Donor couch 3 motors

1 Páginas

-

Deep freezer -40°C

4 Páginas

-

Deep freezer -20°C general

4 Páginas

-

Plasma thawing bath

4 Páginas

-

Stainless steel incubator-agitator

3 Páginas

-

BBR - Solar Powered Horizontal

5 Páginas

-

Blood tube sealer

1 Páginas

-

Portable blood tube sealer

1 Páginas

-

Blood donor couch 3 motors

1 Páginas

-

Blood donor chair

1 Páginas

-

Blood collection chair

1 Páginas

-

Blood Bank Refrigerator touch screen

9 Páginas

-

Blood Bank centrifuge

4 Páginas

-

Biomedical refrigerator

4 Páginas

-

Solar Walk in Cooler

8 Páginas

-

Solar Powered Refrigerator

3 Páginas

-

Solar freezer

7 Páginas

Catálogos arquivados

-

Heated Vacuum Degassing Chamber

1 Páginas

-

Blood Collection Monitor

4 Páginas