Excertos do catálogo

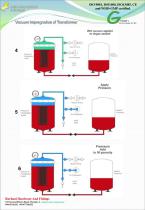

Place Transformer Inside Oven Min 100°C to 125°C vacuum is pulled ‘dry’ on the transformer upto 10 Torr Vacuum Pressure Impregnation (VPI) is the process of treating the finished coils with varnish by placing it a vacuum chamber. First, the transformer is placed in an oven and heated to approximately 100 to 125 ˚C. This heat treatment drives out moisture from the insulation which could otherwise compromise the insulation. After heating, the transformer is placed into the VPI hot. The advantage of doing it this way is that it makes it easier for the varnish to penetrate the insulation to the maximum extent possible since the viscosity of the varnish goes down as it is heated by the coil. Next, the coil is placed in the vacuum chamber and a vacuum is pulled ‘dry’ on the transformer. The varnish is then admitted into the chamber and the vacuum is pulled ‘wet’. Finally, the chamber is pressurized to 100 psi completely filling the coil and insulation with varnish, and then varnish is finally pushed out of the chamber. This results in a coil that is totally saturated with varnish (with atmosphere dip it is only partial). The insulation will then have its maximum dielectric strength and will not absorb moisture (key to longevity). Also, because varnish is a good adhesive, it has better mechanical strength. In addition, because varnish is a good thermal conductor, it runs significantly cooler. The benefit of VPI on the plate transformer is that it reduces the temperature rise by approximately 20%, making it run appreciably cooler and quieter. And the result of that is greater reliability and extended life. This is recognized throughout the transformer industry and is backed up by numerous studies We hope this information is helpful to you as you consider your options for your future designs. We believe that your transformers should all be treated with VPI, particularly given your application. Burhani Hardware And Fittings 110 General Patters Road. Chennai -2 . bhftech.info@gmail.com 044-45116252 +919677296252 Admit Varnish into the Chamber vacuum is pulled ‘wet’ on the transformer chamber is pressurized to 100 psi completely filling the coil and insulation with varnish varnish is finally pushed out

Abrir o catálogo na página 1

Vacuum impregnation is used in many different manufacturing processes to enhance mechanical strength, seal surfaces and to enhance electrical insulation properties. Vacuum Pressure Impregnation (VPI) is the process of treating the finished coils with varnish by placing it a vacuum chamber. One of the most common application for impregnating compounds is in electrical transformer manufacturing. Transformer coils are impregnated for some or all of the following reasons: Increase the overall dielectric strength Improve the structural integrity of the coils Reduce or eliminate winding noise...

Abrir o catálogo na página 2

Burhani Hardware And Fittings 110 General Patters Road. Chennai -2 . www.burhanihardware.org, sales@burhanihardware.org 044-45116252 +919677296252

Abrir o catálogo na página 3

Burhani Hardware And Fittings 110 General Patters Road. Chennai -2 . bhftech.info@gmail.com 044-45116252 +919677296252

Abrir o catálogo na página 4

Burhani Hardware And Fittings 110 General Patters Road. Chennai -2 . bhftech.info@gmail.com 044-45116252 +919677296252

Abrir o catálogo na página 5Todos os catálogos e folhetos técnicos Meditech Technologies India

-

Vacuum Glove Box Metal Body

4 Páginas

-

stainless steel Vacuum Chamber Cube

1 Páginas

-

S S vacuum Chamber for degassing

1 Páginas

-

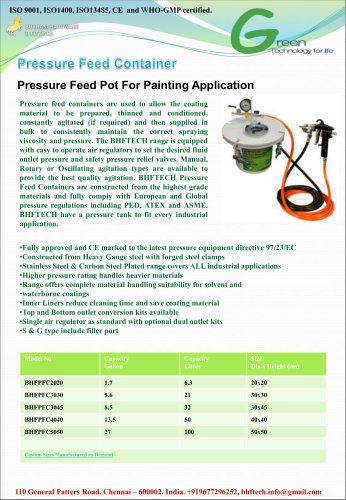

Pressure Pot For Resin casting

1 Páginas

-

Potting of Elecronic Components

3 Páginas

-

Heated Vacuum Oven

1 Páginas

-

EXPOXY RESIN BURHANI

2 Páginas

-

CLEAR CASTING RESIN-POLYSTER

1 Páginas

-

Acrylic vacuum glove box

2 Páginas

-

Acrylic Vacuum Chamber Cylinder

1 Páginas

-

Acrylic Vacuum Chamber Cube

1 Páginas

-

acrlic vacuum glove box

2 Páginas

-

vacuum leak detector chamber cube

1 Páginas

-

vacuum degassing chamber ss tank

1 Páginas

-

Vacuum Degasser Transparent Cylinder

1 Páginas

-

Vacuum Degasser Transparent Cube

1 Páginas

-

SS Vacuum Chamber for drying

1 Páginas

-

SS Vacuum Degassing Chamber

1 Páginas

-

resin degassing vacuum chamber

2 Páginas

-

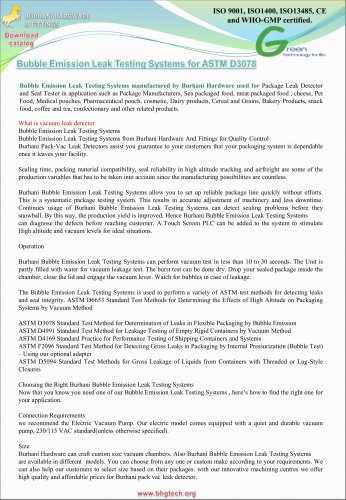

pack vac leak detector

2 Páginas

-

clear acrylic round vacuum chamber

1 Páginas

-

clear acrylic cube vacuum chamber

1 Páginas

-

xenon test chamber

3 Páginas

-

walk in stability chamber

12 Páginas

-

walk in cooler

11 Páginas

-

thermo hygrostat chamber

10 Páginas

-

plant growth room

2 Páginas

-

photostability chamber

9 Páginas

-

humidity temp stability chamber

7 Páginas

-

Humidity Chamber

10 Páginas

-

Freezer thaw chamber

9 Páginas

-

cold room

10 Páginas

-

cold room for blood bank

18 Páginas

-

co2 incubator

15 Páginas

-

BOD Incubator

10 Páginas

-

Bacteriological Incubator

4 Páginas

-

meditech dc compressor

3 Páginas

-

Solar DC Compressor

3 Páginas

-

Digital Physiograph Meditech

2 Páginas

-

stability chamber

7 Páginas

-

Blood Bank Tube sealer

1 Páginas

-

Blood Bank refrigerator tp series

12 Páginas

-

solar ice lined refrigerator

4 Páginas

-

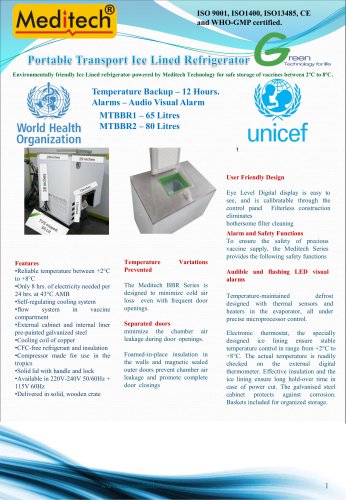

ice lined refrigerator meditech

5 Páginas

-

Solar DC Refrigerator Freezer

4 Páginas

-

platelet incubator agitator

3 Páginas

-

Blood Donor Coach Chair

1 Páginas

-

Blood Collection Monitor Meditech

5 Páginas

-

Biomedical lab Refrigerator

4 Páginas

-

Laboratory Refrigerator Touch Screen

8 Páginas

-

Incubator

2 Páginas

-

Pharmacy Refrigerator Meditech

4 Páginas

-

Meditech Blood Bank Equipments

41 Páginas

-

Incubator Meditech

2 Páginas

-

Phlebotomy Chair Meditech

1 Páginas

-

Blood Donor Chair Meditech

1 Páginas

-

Bio Medical Training Kit Meditech

2 Páginas

-

Digital Physiograph Meditech Online

2 Páginas

-

Mobile Blood Donor Couches

1 Páginas

-

Vertical Ice Lined Refrigerator

6 Páginas

-

Horizontal Ice Lined Refrigerator

4 Páginas

-

Blood Tube Sealer

1 Páginas

-

MTCR 60

6 Páginas

-

MTPS432

5 Páginas

-

MTPS360

5 Páginas

-

MTPS288

5 Páginas

-

MTPS216

5 Páginas

-

MTPS144

5 Páginas

-

MTPS72

5 Páginas

-

MBDW80

11 Páginas

-

MBDW120

11 Páginas

-

MBDW40

11 Páginas

-

Portable Refrigerator

2 Páginas

-

Laminar Air Flow Horizontal

1 Páginas

-

Blood Bank Refrigerated centrifuge

4 Páginas

-

Blood Storage Refrigerator

18 Páginas

-

Camping Cot

1 Páginas

-

MTR30

3 Páginas

-

MTR26

3 Páginas

-

ME7-2

3 Páginas

-

ME8

8 Páginas

-

MTBDR16

3 Páginas

-

MTAC60

7 Páginas

-

MTAC40

7 Páginas

-

MTAC26

3 Páginas

-

MA1000

3 Páginas

-

Respiration Pump

1 Páginas

-

Spirometer

1 Páginas

-

Smoking Burner & Stand

1 Páginas

-

Varnishing Outfit

1 Páginas

-

Elisa Plate Analyser

2 Páginas

-

Solar Blood Bank Refrigerator

6 Páginas

-

mushroom grow chamber

9 Páginas

-

Walk in type cooling cabinet

12 Páginas

-

Walk in stability chambers

12 Páginas

-

Walk in freezer

11 Páginas

-

Walk in cooler for Blood Bank

18 Páginas

-

Thermo Hygrostat Incubator

10 Páginas

-

Temperature Rooms - Hot Cold

9 Páginas

-

Temperature Chamber

7 Páginas

-

Humidity Temperature Stability Room

7 Páginas

-

Direct heat CO2 incubator

15 Páginas

-

Cold rooms

10 Páginas

-

Cold rooms for Blood Bank

18 Páginas

-

CO2 incubator

7 Páginas

-

Ultra Low Plasma freezer with backup

6 Páginas

-

Ultra Low Plasma freezer horizontal

4 Páginas

-

Ultra Low Deep freezer -40°C with Touch

11 Páginas

-

Ultra Low Deep freezer with touch

11 Páginas

-

Solar Powered Deep freezer -40°C

4 Páginas

-

Reagent Refrigerator

4 Páginas

-

Platelet agitator

7 Páginas

-

Plasmatherm plasma thawing bath

2 Páginas

-

Phlebotomy chair

1 Páginas

-

Pharmacy refrigerator

4 Páginas

-

Lab refrigerator

4 Páginas

-

Donor couch 3 motors

1 Páginas

-

Deep freezer -40°C

4 Páginas

-

Deep freezer -20°C general

4 Páginas

-

Plasma thawing bath

4 Páginas

-

Stainless steel incubator-agitator

3 Páginas

-

BBR - Solar Powered Horizontal

5 Páginas

-

Blood tube sealer

1 Páginas

-

Portable blood tube sealer

1 Páginas

-

Blood donor couch 3 motors

1 Páginas

-

Blood donor chair

1 Páginas

-

Blood collection chair

1 Páginas

-

Blood Bank Refrigerator touch screen

9 Páginas

-

Blood Bank centrifuge

4 Páginas

-

Biomedical refrigerator

4 Páginas

-

Solar Walk in Cooler

8 Páginas

-

Solar Powered Refrigerator

3 Páginas

-

Solar freezer

7 Páginas

Catálogos arquivados

-

Heated Vacuum Degassing Chamber

1 Páginas

-

Blood Collection Monitor

4 Páginas